Vous êtes ici

UB-4000A - Unité de contrôle de soudage par point CC linéaire avec moniteur intégré (anciennement connu sous le nom de DC29)

L’unité de soudage par résistance CC linéaire UB-4000A est un contrôle CC linéaire à 200 -4 000 ampères avec quatre modes de retour conçus pour s’adapter à la pièce et aux variables de procédé. L’énergie de soudage peut être programmée en courant, en tension, en puissance ou V-A, par incréments aussi courts que 0,01 milliseconde. Le soudeur par point est ainsi idéal pour les petites applications des marchés des composants électroniques et des blocs de batterie.

Caractéristiques UB-4000A - Unité de contrôle de soudage par point CC linéaire avec moniteur intégré

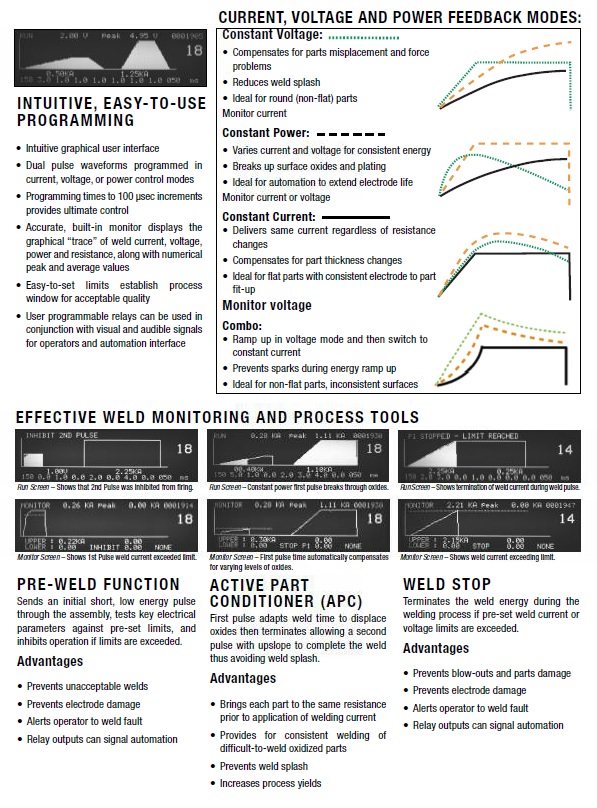

- Quatre modes de contrôle : courant, tension, puissance et V-A (courant-tension)

- Entrée monophasée

- Dimension compacte

- Programmes à double impulsion

- Onde de forme reproductible contrôlée avec précision

- Temps de montée très rapide

| Numéro de modèle | UB-500A | UB-1500A | UB-4000A | |||

|---|---|---|---|---|---|---|

| Tensions de ligne nominales (monophasées) | 88-264 VAC 47-63 Hz | 88-264 VAC 47-63 Hz | 88-264 VAC 47-63 Hz | |||

| Taux de répétition | 500 A @ 3 weld/sec for 10 ms (per weld) | 1500 A @ 1 weld/sec for 10 ms (per weld) | 4000 A @ 1 weld/sec for 10 ms (per weld) | |||

| Plages de réglage : Courant | 5A-500A 1 amp/step | 15A-1500A 1 amp/step | 200 A - 4000 A 10 amp/step | |||

| Plages de réglage : Tension | 0.01 V - 9.9 V 10 mV/step | 0.1 V - 9.9 V 10 mV/step | 0.1 V - 9.9 V 10 mV/step | |||

| Plages de réglage : Puissance | 0.05 kW - 4.99 kW 10 Watt/step | 0.1 kW - 9.9kW 10 Watt/step | 0.1 kW - 25.0kW 10 Watt/step | |||

| Crête : Courant | 500 A | 1500 A | 4000 A | |||

| Crête : Tension | 10 V | 10 V | 10 V | |||

| Crête : Puissance | 4.9 kW | 9.9 kW | 25.0 kW | |||

| Régulation de la sortie en fonction de la variance de la tension de ligne | 2% | 2% | 2% | |||

| Régulation de la sortie en fonction de la variance de la résistance à la charge | 2% | 2% | 2% | |||

| Plages de période de soudage | Ranges (ms) | Resolution (steps) | Ranges (ms) | Resolution (steps) | Ranges (ms) | Resolution (steps) |

| Périodes de première / deuxième impulsion, de croissance / décroissance et de refroidissement | 0 - 99.9 | .1(0-9.9), 1(10-99) | 0 - 99.9 | .1(0-9.9), 1(10-99) | 0 - 99.9 | .1(0-9.9), 1(10-99) |

| Squeeze/hold periods | 0-999 | 1 | 0-999 | 1 | 0-999 | 1 |

| Précision de sortie : Courant | ±2% or 2.5 A | ±2% or 7 A | ±2% or 10 A | |||

| Précision de sortie : Tension | ±2% or 0.05 V | ±2% or 0.05 V | ±2% or 0.05 V | |||

| Précision de sortie : Puissance | ±5% or 12 W | ±5% or 40 W | ±5% or 50 W | |||

| Caractéristiques | . | |||||

| Contrôle du profil thermique de soudage | UB-500A | UB-1500A | UB-4000A | |||

| Contrôle des impulsions de soudage | Dial pulse with independent control of current, voltage or power on each pulse | Dial pulse with independent control of current, voltage or power on each pulse | Dial pulse with independent control of current, voltage or power on each pulse | |||

| Segments d'impulsion de soudage programmables | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | |||

| Mémoire de programmes de soudage | Save up to 99 different weld schedules, protected from unauthorized changes | Save up to 99 different weld schedules, protected from unauthorized changes | Save up to 99 different weld schedules, protected from unauthorized changes | |||

| Weld schedule chaining | Allows automatic linking of weld schedule sequence | Allows automatic linking of weld schedule sequence | Allows automatic linking of weld schedule sequence | |||

| Built-in weld monitor functions | ||||||

| Paramètres de mesure | Current, voltage, power, resistance on each pulse. | Current, voltage, power, resistance on each pulse. | Current, voltage, power, resistance on each pulse. | |||

| Affichage graphique | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | |||

| Measurement selection | Peak or average | Peak or average | Peak or average | |||

| Plage / précision de mesure du courant | 0 – 500 A, ±2% of setting ±5 A | 0 – 1500 A, ±2% of setting ±10 A | 0 – 4000kA, ±2% of setting ±20 A | |||

| Plage / précision de mesure de la tension | 0.1 – 9.9 V, ±2% of setting ±0.05 V | 0.01 – 9.9 V, ±2% of setting ±0.05 V | 0.01 – 9.9 V, ±2% of setting ±0.05 V | |||

| Plage / précision de mesure de la puissance | 0 – 4.9 kW, ±5% of setting ±10 W | 0 - 9.99 kV, ±2% of setting ±40 W | 0 – 25.0 kW, ±5% of setting ±50 W | |||

| Alarmes | Display alert, five user programmable AC/DC relays; audio alarm | Display alert, five user programmable AC/DC relays; audio alarm | Display alert, five user programmable AC/DC relays; audio alarm | |||

| Limite d'énergie de soudage programmable | Terminates weld energy when exceeding user defined current, voltage, or power limits | Terminates weld energy when exceeding user defined current, voltage, or power limits | Terminates weld energy when exceeding user defined current, voltage, or power limits | |||

| Pré-contrôles de soudage | Inhibits second weld pulse when first test pulse exceeds user programmed limits | Inhibits second weld pulse when first test pulse exceeds user programmed limits | Inhibits second weld pulse when first test pulse exceeds user programmed limits | |||

| Conditionneur de pièce active | First pulse current limit in constant power | First pulse current limit in constant power | First pulse current limit in constant power | |||

| Communications E/S et données | ||||||

| Input: Input Isolation | All inputs and outputs are fully isolated | All inputs and outputs are fully isolated | All inputs and outputs are fully isolated | |||

| Input: Control voltages | +24V, sourcing or sinking inputs | +24V, sourcing or sinking inputs | +24V, sourcing or sinking inputs | |||

| Input: Foot switch initiation | 1-level foot switch, 2-level foot switch | 1-level foot switch, 2-level foot switch | 1-level foot switch, 2-level foot switch | |||

| Input: Firing switch initiation | Mechanical or opto firing switch | Mechanical or opto firing switch | Mechanical or opto firing switch | |||

| Input: Remote control | Remote weld schedule select, process inhibit, emergency stop, alarm reset | Remote weld schedule select, process inhibit, emergency stop, alarm reset | Remote weld schedule select, process inhibit, emergency stop, alarm reset | |||

| Input: RS232 | Change weld schedules and individual parameters | Change weld schedules and individual parameters | Change weld schedules and individual parameters | |||

| Input: Electrode voltage | Weld voltage signal for voltage feedback operation (0 to 10V peak) | Weld voltage signal for voltage feedback operation (0 to 10V peak) | Weld voltage signal for voltage feedback operation (0 to 10V peak) | |||

| Output: Monitor | RS232 weld data out | RS232 weld data out | RS232 weld data out | |||

| Output: Weld head air valve driver | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | |||

| Output: Alarm relays | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | |||

| Dimensions (L x l x H) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | |||

| Poids | 22 kg (49 lb) | 22 kg (49 lb) | 22 kg (49 lb) |

Documentation

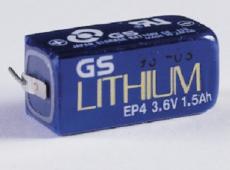

Battery tab to lithium ion cell

Halogen lamp filaments

Catheter guide wire assembly

Air bag detonator module (squib wire)

Solutions personnalisées

Envoyez votre échantillon à un de nos centres technologiques en Europe pour une expertise. Nous déterminerons ensuite la meilleure solution pour répondre à vos besoins. AMADA WELD TECH propose des tests de faisabilité et des conseils d’application.