Tu sei qui

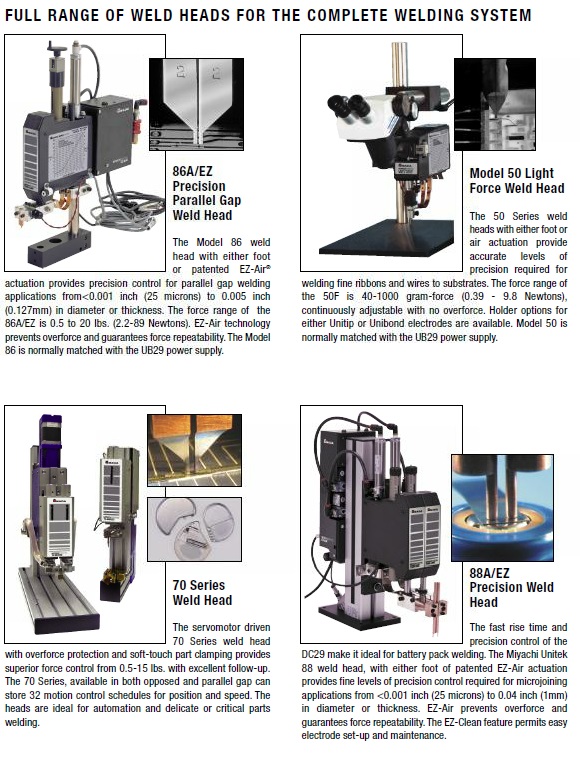

UB-4000A - Controllo di saldatura a punti DC lineare con monitor incorporato (precedentemente conosciuto come DC29)

UB-4000A è un controllo per saldatura a resistenza DC lineare da 200–4000 A con quattro modalità di retroazione progettate per adattarsi alle variabili di processo e del pezzo. L'energia di saldatura può essere programmata in corrente, tensione, potenza o V-A, con incrementi di appena 0,01 millisecondi. Pertanto, questa saldatrice a punti è ideale per piccole applicazioni del settore componenti elettronici e batterie ricaricabili.

Specifiche UB-4000A - Controllo di saldatura a punti DC lineare con monitor incorporato

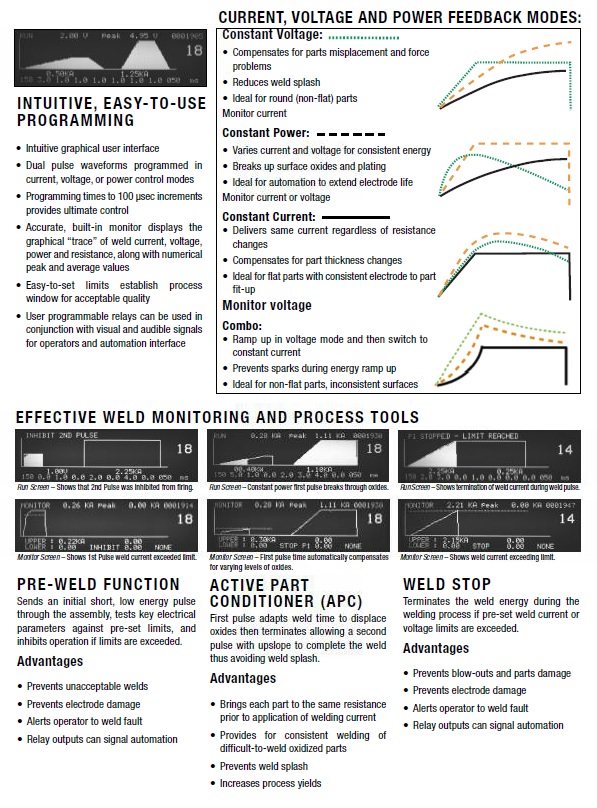

- Quattro modalità di controllo: corrente, tensione, potenza e V-A (tensione-corrente)

- Ingresso monofase

- Dimensione compatta

- Programmazioni a doppio impulso

- Forma d'onda ripetibile controllata con precisione

- Tempo di salita molto rapido

| Numero di modello | UB-500A | UB-1500A | UB-4000A | |||

|---|---|---|---|---|---|---|

| Tensioni di linea nominali (monofase) | 88-264 VAC 47-63 Hz | 88-264 VAC 47-63 Hz | 88-264 VAC 47-63 Hz | |||

| Velocità di ripetizione | 500 A @ 3 weld/sec for 10 ms (per weld) | 1500 A @ 1 weld/sec for 10 ms (per weld) | 4000 A @ 1 weld/sec for 10 ms (per weld) | |||

| Campi di impostazione: Corrente | 5A-500A 1 amp/step | 15A-1500A 1 amp/step | 200 A - 4000 A 10 amp/step | |||

| Campi di impostazione: Tensione | 0.01 V - 9.9 V 10 mV/step | 0.1 V - 9.9 V 10 mV/step | 0.1 V - 9.9 V 10 mV/step | |||

| Campi di impostazione: Potenza | 0.05 kW - 4.99 kW 10 Watt/step | 0.1 kW - 9.9kW 10 Watt/step | 0.1 kW - 25.0kW 10 Watt/step | |||

| Picco: Corrente | 500 A | 1500 A | 4000 A | |||

| Picco: Tensione | 10 V | 10 V | 10 V | |||

| Picco: Potenza | 4.9 kW | 9.9 kW | 25.0 kW | |||

| Regolazione di uscita rispetto a varianza tensione di linea | 2% | 2% | 2% | |||

| Regolazione di uscita rispetto a varianza resistenza carico | 2% | 2% | 2% | |||

| Intervalli periodo saldatura | Ranges (ms) | Resolution (steps) | Ranges (ms) | Resolution (steps) | Ranges (ms) | Resolution (steps) |

| Primo/secondo impulso, periodi di raffreddamento e salita/discesa | 0 - 99.9 | .1(0-9.9), 1(10-99) | 0 - 99.9 | .1(0-9.9), 1(10-99) | 0 - 99.9 | .1(0-9.9), 1(10-99) |

| Squeeze/hold periods | 0-999 | 1 | 0-999 | 1 | 0-999 | 1 |

| Precisione uscita: Corrente | ±2% or 2.5 A | ±2% or 7 A | ±2% or 10 A | |||

| Precisione uscita: Tensione | ±2% or 0.05 V | ±2% or 0.05 V | ±2% or 0.05 V | |||

| Precisione uscita: Potenza | ±5% or 12 W | ±5% or 40 W | ±5% or 50 W | |||

| Caratteristiche | . | |||||

| Controllo profilo testa di saldatura | UB-500A | UB-1500A | UB-4000A | |||

| Controllo impulso saldatura | Dial pulse with independent control of current, voltage or power on each pulse | Dial pulse with independent control of current, voltage or power on each pulse | Dial pulse with independent control of current, voltage or power on each pulse | |||

| Segmenti impulso di saldatura programmabili | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | |||

| Memoria programma saldatura | Save up to 99 different weld schedules, protected from unauthorized changes | Save up to 99 different weld schedules, protected from unauthorized changes | Save up to 99 different weld schedules, protected from unauthorized changes | |||

| Weld schedule chaining | Allows automatic linking of weld schedule sequence | Allows automatic linking of weld schedule sequence | Allows automatic linking of weld schedule sequence | |||

| Built-in weld monitor functions | ||||||

| Parametri di misurazione | Current, voltage, power, resistance on each pulse. | Current, voltage, power, resistance on each pulse. | Current, voltage, power, resistance on each pulse. | |||

| Display grafico | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | |||

| Measurement selection | Peak or average | Peak or average | Peak or average | |||

| Precisione/campo misurazione corrente | 0 – 500 A, ±2% of setting ±5 A | 0 – 1500 A, ±2% of setting ±10 A | 0 – 4000kA, ±2% of setting ±20 A | |||

| Precisione/campo di misurazione tensione | 0.1 – 9.9 V, ±2% of setting ±0.05 V | 0.01 – 9.9 V, ±2% of setting ±0.05 V | 0.01 – 9.9 V, ±2% of setting ±0.05 V | |||

| Precisione/campo misurazione alimentazione | 0 – 4.9 kW, ±5% of setting ±10 W | 0 - 9.99 kV, ±2% of setting ±40 W | 0 – 25.0 kW, ±5% of setting ±50 W | |||

| Allarmi | Display alert, five user programmable AC/DC relays; audio alarm | Display alert, five user programmable AC/DC relays; audio alarm | Display alert, five user programmable AC/DC relays; audio alarm | |||

| Limite energia di saldatura programmabile | Terminates weld energy when exceeding user defined current, voltage, or power limits | Terminates weld energy when exceeding user defined current, voltage, or power limits | Terminates weld energy when exceeding user defined current, voltage, or power limits | |||

| Precontrollo saldatura | Inhibits second weld pulse when first test pulse exceeds user programmed limits | Inhibits second weld pulse when first test pulse exceeds user programmed limits | Inhibits second weld pulse when first test pulse exceeds user programmed limits | |||

| Condizionatore parte attiva | First pulse current limit in constant power | First pulse current limit in constant power | First pulse current limit in constant power | |||

| Comunicazioni dati e I/O | ||||||

| Input: Input Isolation | All inputs and outputs are fully isolated | All inputs and outputs are fully isolated | All inputs and outputs are fully isolated | |||

| Input: Control voltages | +24V, sourcing or sinking inputs | +24V, sourcing or sinking inputs | +24V, sourcing or sinking inputs | |||

| Input: Foot switch initiation | 1-level foot switch, 2-level foot switch | 1-level foot switch, 2-level foot switch | 1-level foot switch, 2-level foot switch | |||

| Input: Firing switch initiation | Mechanical or opto firing switch | Mechanical or opto firing switch | Mechanical or opto firing switch | |||

| Input: Remote control | Remote weld schedule select, process inhibit, emergency stop, alarm reset | Remote weld schedule select, process inhibit, emergency stop, alarm reset | Remote weld schedule select, process inhibit, emergency stop, alarm reset | |||

| Input: RS232 | Change weld schedules and individual parameters | Change weld schedules and individual parameters | Change weld schedules and individual parameters | |||

| Input: Electrode voltage | Weld voltage signal for voltage feedback operation (0 to 10V peak) | Weld voltage signal for voltage feedback operation (0 to 10V peak) | Weld voltage signal for voltage feedback operation (0 to 10V peak) | |||

| Output: Monitor | RS232 weld data out | RS232 weld data out | RS232 weld data out | |||

| Output: Weld head air valve driver | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | |||

| Output: Alarm relays | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | |||

| Dimensioni (LxPxA) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | |||

| Massa | 22 kg (49 lb) | 22 kg (49 lb) | 22 kg (49 lb) |

Documentation

Battery tab to lithium ion cell

Halogen lamp filaments

Catheter guide wire assembly

Air bag detonator module (squib wire)

Soluzioni personalizzate

Inviate un campione a uno dei nostri centri tecnologici in Europa per una valutazione. Valuteremo la soluzione che soddisfa meglio le vostre esigenze. AMADA WELD TECH conduce test di fattibilità e eroga consulenza applicativa.