You are here

Laser Spot Welding

Laser spot welding is a non-contact process which uses a laser to create a single weld spot to weld metals together. Lasers are capable of delivering a pulse of light with accurate, repeatable energy and duration. When the pulse is focused into one place - a small spot - (adjustable anywhere from approximately 0.1 to 2.0 mm in diameter) on the part, the energy density becomes quite large. The light is absorbed by the material causing a "keyhole effect" as the focused beam drills into, vaporizes, and melts some of the metal. As the pulse ends, the liquefied metal around the keyhole flows back in, solidifying and creating a small spot weld. This entire process just a few milliseconds.

Lasers can fire many pulses per second, and, by moving either the work piece or optics, allow either separate "spot" welds or a series of overlapping spot welds to create a laser seam weld that can be structurally sound and/or hermetic.

Laser Spot Welding Benefits:

AMADA WELD TECH lasers welders can join a wide range of steels, nickel alloys, titanium, aluminium and copper.

Weld sizes:

Width: 10 nm - 1000 nm

Depth: 10 nm - 5 mm

Welding speeds:

Range from 0 - 1 meter per second

- Easy to integrate into production lines

- Small heat affected zone

- Contactless welding

- Very fast welding

- Low costs per weld for high volume spot-weld application

AMADA WELD TECH also offers:

Laser Seam Welding

Resistance Spot Welding

Applications of Laser Welding

Typical applications of laser spot welding include coil welding with sub 100 micro spot welds,

high speed welding of copper tabs to steel battery cans, wire to ring spot welding, medical tool welding and many more.

High speed welding

Placing of up to 50 spots per second each in a different location by using a laser scanner weld solution

Small heat affected zone needed

When small spot sizes are required to avoid damaging the materials or electrical components close to the weld area

Difficult access

Weld parts over molded components where traditional resistance welding heads have difficulty accessing

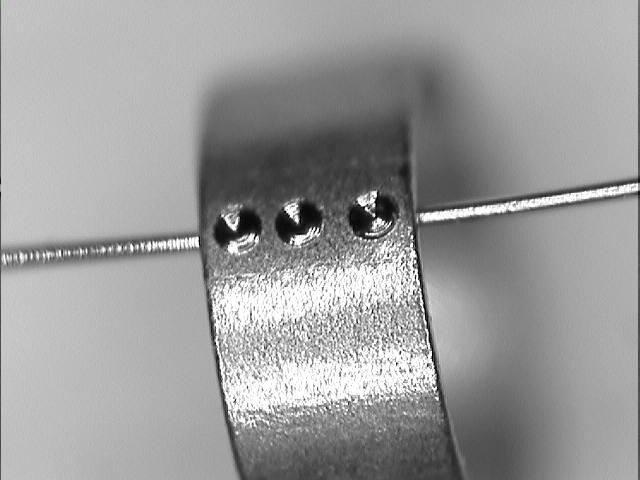

Simultaneous weld on multiple spots

To maintain alignment of parts, the part is welded with at 2 or 3 spots simultaneously thru an energy share set-up of the laser.