You are here

Percussive Arc Welding

Percussive arc welding is the process of combining micro arc TIG welding with a mechanical “percussive” movement that forces the arcing components together. The heat from the arc creates two molten interfaces which, when pushed together, fuse as a weld and extinguish the arc, forming a butt weld.

The process is very quick and controllable and, as such, requires high-speed real-time control elements and a degree of programmable flexibility to deliver a manufacturing standard system.

Percussive Arc Welding Applications

Typical percussive arc welding applications are:

- Butt welding of thin wires

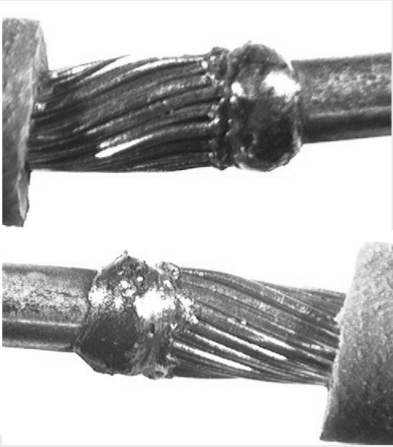

- Stranded wire to pin joining

- Blind thermocouple welding

Welding wire to component pin

- The two parts are first held apart and aligned with an adjustable jig.

- An arc is struck between the wire and the component lead, immediately starting to ball the wire end and consolidating the strands.

- After a matter of milliseconds, the wire is mechanically accelerated towards the pin end to create a controlled impact, enabling the two molten ends fuse and weld together. This is detected electronically, the arc extinguishes and the current flow is reduced to zero.

Blind butt welding

A frequent requirement and use of percussive arc welding is in blind butt welding within cavities or containers. In this instance, the diagram shows how a thermocouple can be welded to the inside of a tube through a small opening.

Blind thermocouple placement and welding

With this technique, the TIG welding capability can also be configured to “ball end“ the thermocouple prior to its placement and welding. Similarly, pins, stranded wires, solid wires, electronic components etc. can be butt welded in place with high-integrity, high-temperature resistant joints.

Contact a MacGregor Welding Systems expert now!

We have built a reputation upon providing welding expertise, coupled with high-quality products and service