You are here

Projection Welding

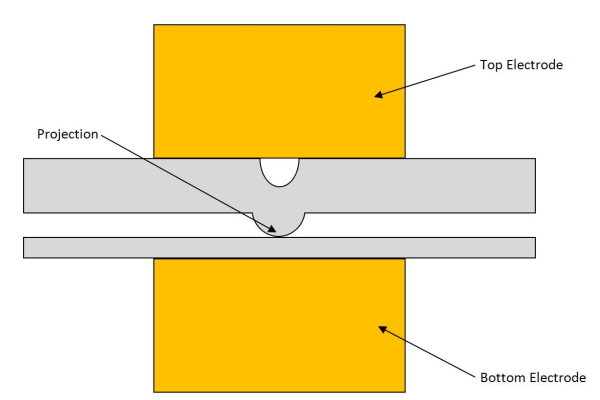

Projections (low thermal-mass islands) are one method of insuring proper heat balance in difficult spot-welding applications when there the parts to be welded vary in size by 5:1. By providing a projection on the surface of one of the workpieces, weld current and force can be focused into the small area of the projection to produce heat at the desired weld location. Projection welding can extend electrode life by increasing the electrode contact area and decreasing the current density at the surface of the electrode. Projection welding is effective even if the weldments are thick.

Projection welding differs from spot welding in that one or more projections are attached to one of the two workpieces that are to be joined. The projection forms a defined current conduction point. The parts are placed on top of each other and welded together at this point using large-area electrodes by means of a current pulse under the influence of the electrode force. Several projections can also be welded at the same time.

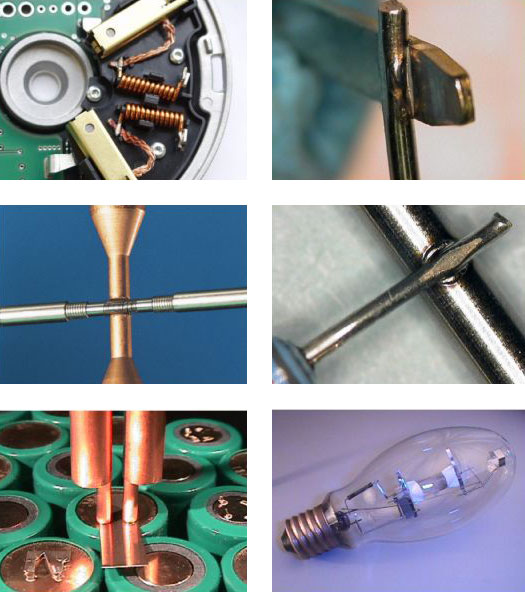

Projection Welding Applications

Benefits of Projection Welding:

- The welding current is concentrated on the joint using a projection or profile on one of the individual parts.

- Flat electrodes with a large contact surface area can be used that have a shape matching the area of the workpiece.

- The use of flat electrodes means longer shelf-life, virtually no deformation or discoloration on the workpiece and perfect fit in high-volume production applications.

- This resistance welding method is also designed to allow for multi-projection welding whereby a corresponding number of electrodes or a pair of large-surface electrodes is fed from a single power source.

In addition to projection welding, AMADA WELD TECH offers the following resistance welding methods:

For more information regarding designing projections, see AMADA WELD TECH's blogs 'Projection Welding: Balance Heat and Extend Electrode Life' and 'Designing Ring Projections for Hermetic Sealing.'