You are here

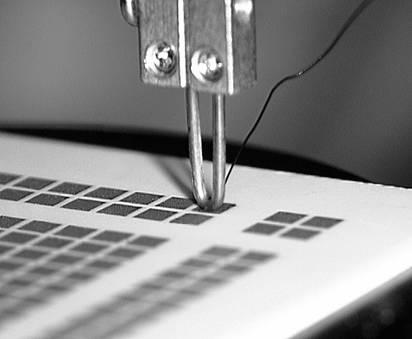

Pulse Tip Bonding to metallised substrates

Pulse Tip Bonding is a highly effective process in which insulated magnet wire, copper or aluminium may be bonded directly to a metallised substrate, without the need to strip the wire or use and apply solder.

The pulse tip process offers a simple alternative to conventional methods of magnet wire attachment.

For many applications, it can simplify the process by eliminating the need for cumbersome solder and stripping of the wire.

Pulse Tip Bonding Equipment

MacGregor Welding Systems has vast experience in Pulse Tip Bonding and can offer you the correct equipment for your specific Pulse Tip Bonding application.

The equipment required for this process:

1) Special Pulse Tip – to suit application

2) The MACGREGOR m1 or DC613-T Power Supply

3) Constant force Bond Head

4) Optics Package

5) Fibre-optic Illuminator

Contact a bonding specialist at MacGregor Welding Systems for more information.

The Pulse Tip Bonding process

The pulse tip design coupled with a unique bonding and control process creates two simultaneous events.

1) Firstly, the special high-temperature bonding tip vaporises the wire insulation.

2) Secondly, under-real-time force and temperature control, the tip is used to produce a thermocompression bond.

This process totally eliminates the need to strip the wire prior to bonding or the need for solder. As a process, it is applicable to a wide range of wire types and substrates and is particularly beneficial on ceramic substrates where troublesome high-temperature solders are generally required.

The process can also be used in conjunction with standard SnPb solder pads.

The energy used for the process is delivered from a precision closed-loop micro controlled power supply which generates a very high, instantaneous pulse of heating energy.

The amount of heat is readily adjustable and precisely controlled from joint to joint.