You are here

Resistance Welding

Resistance welding is a thermo-electric process in which heat is generated at the interface of the parts to be joined. It works by passing an electrical current through the parts for a precisely controlled time and under a controlled pressure also called the force. The name “resistance” welding derives from the fact that the resistance of the workpieces and electrodes are used in combination or contrast to generate heat at their interface.

Key advantages of the resistance welding process include:

- Very short process time

- No consumables, such as brazing materials, solder, or welding rods

- Operator safety due to low voltage

- Clean and environmentally friendly

- A reliable electro-mechanical joint is formed

Resistance Welding methods - the heat generation process

Resistance welding is a fairly simple heat generation process: the passage of current through a resistance generates heat. This is the same principle used in heating coils. In addition to the bulk resistances, contact resistances also play a major role. The contact resistances are influenced by the surface condition (surface roughness, cleanliness, oxidation, and plating).

Four main parameters influence the quality of resistance welding and need to be monitored closely to achieve top class results:

- Materials

- Energy

- Weld Force

- Time

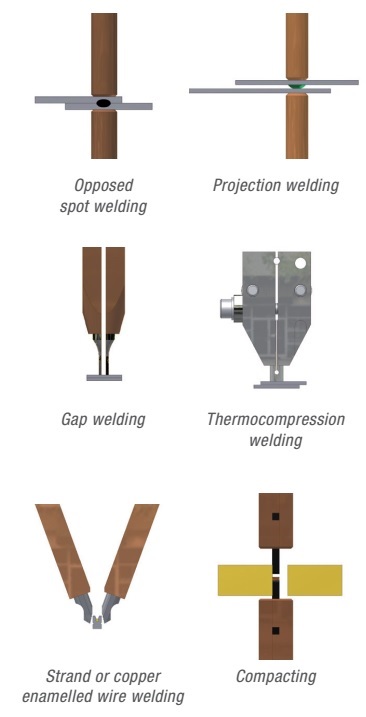

AMADA WELD TECH offers a wide range of welding methods which have been successfully used for decades, such as opposed welding. A selection of five different welding methods are described in the links below and illustrated on the right-hand side:

Spot Welding

Projection Welding

Gap Welding

Thermocompression welding

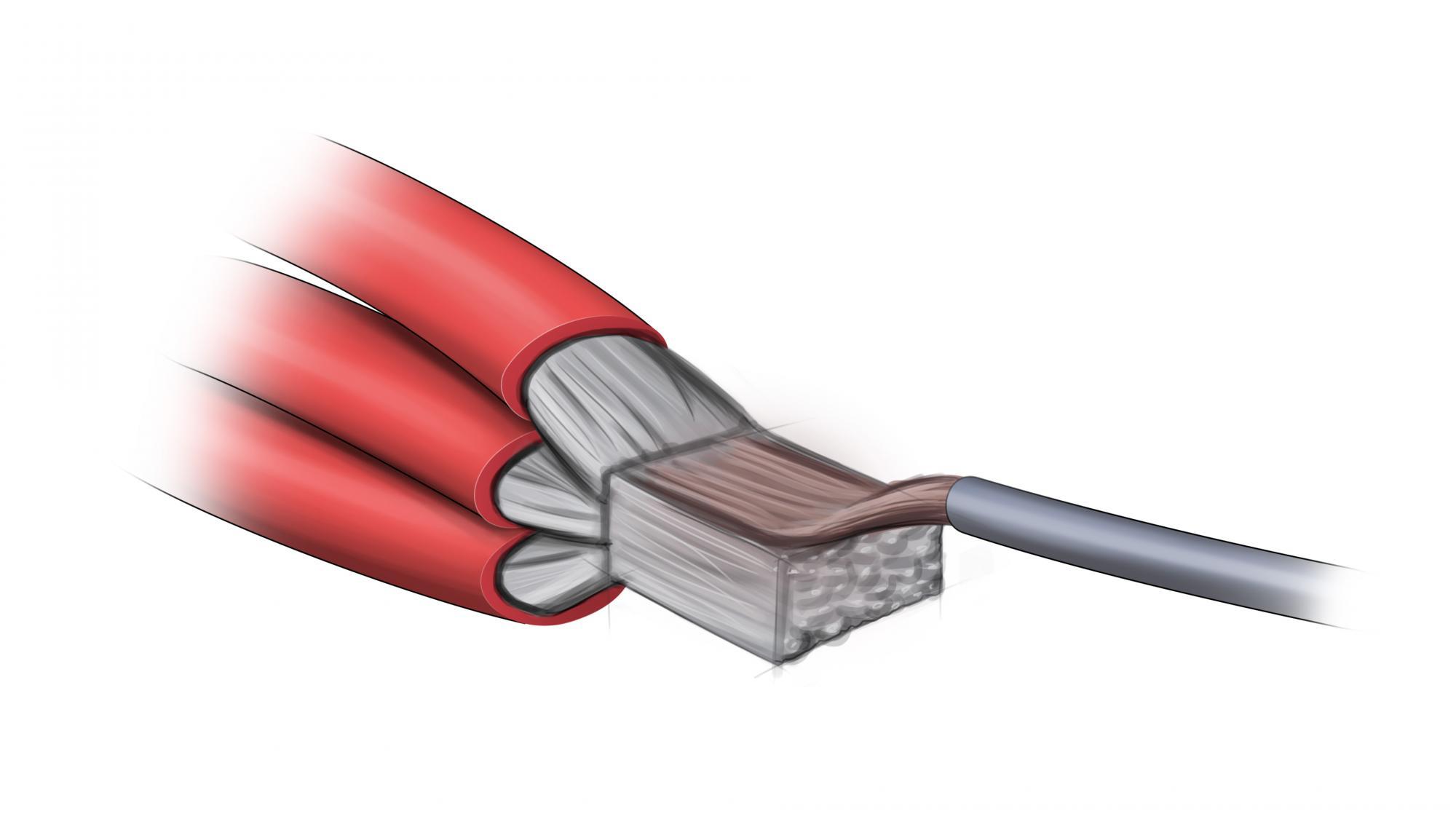

Strand welding

Insulated Wire Welding

Our team will guide you through practical fixes for technical challenges which may occur during the welding process.

Learn more about the feasible technical options for resistance welding from our Weldability Chart

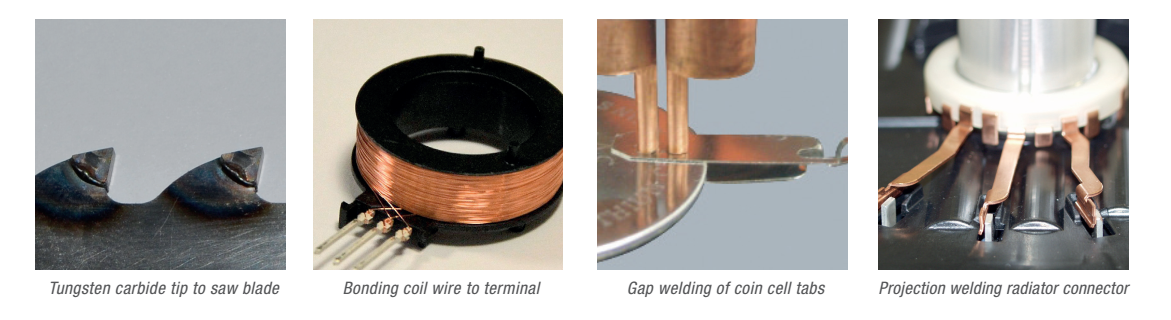

Typical Resistance Welding Applications