You are here

Seam Welding

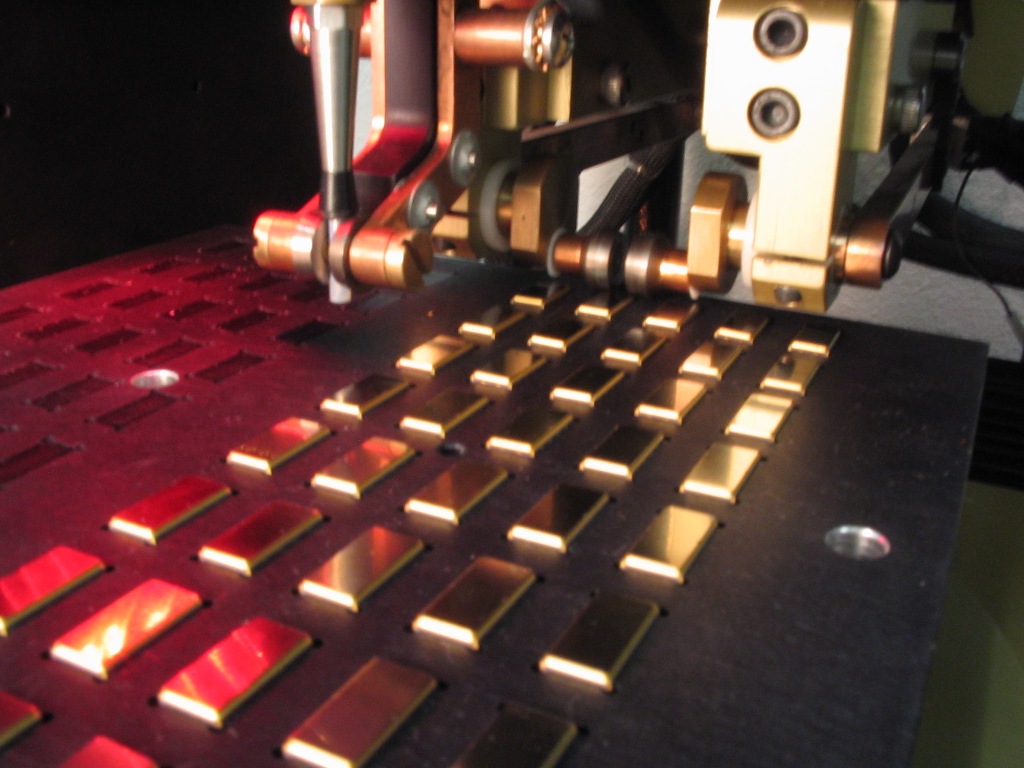

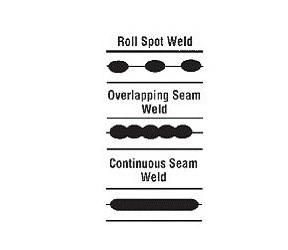

Seam welding is a variation of resistance spot welding. In resistance seam welding, the welding electrodes are positioned on motorised wheels as opposed to stationary rods. This results in a 'rolling' resistance weld or non-hermetic seam weld. This process is most often used to join two sheets of metal together.

There are various methods for generating a seam weld. The most feasible method depends on the application. AMADA WELD TECH offers seam welding using Resistance Welding or Laser Welding technologies.

Seam Welding Equipment

AMADA WELD TECH offers a complete line of seam welding systems including projection welders, rotary welders, hermetic seam sealing systems, and lid placement and tacking systems.

Hermetic Sealing Systems may be integrated with any of our power supplies for resistance welding or hot bar reflow soldering. Laser systems are also available.

Because AMADA WELD TECH designs and manufactures both the power supply and the hermetic sealing system, you are assured that the motion, power supply, software, and tooling will work properly and are integrated into a whole that supports your desired process flow.