You are here

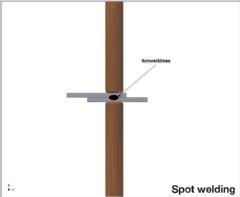

Spot Welding

AMADA WELD TECH offers a variety of resistance welding methods. In spot welding, the parts to be welded lie on top of each other, with their surfaces touching, in point or line form.

The welding current is supplied by the spot-welding electrodes. When the welding temperature is reached, the parts are welded in spots at the contact points between the electrodes by means of the electrode force.

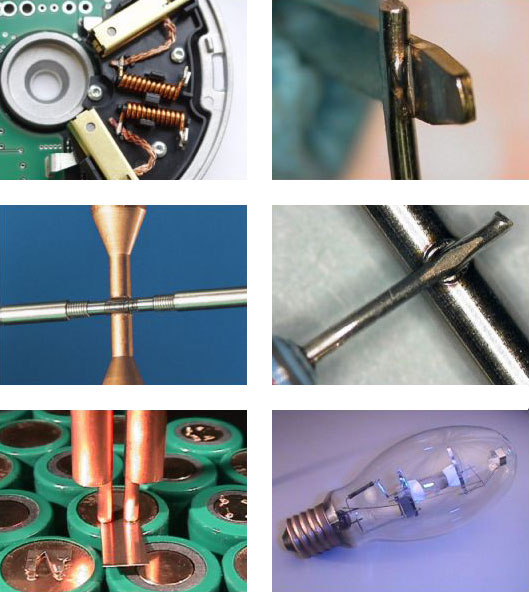

Spot Welding Applications:

Benefits of Spot Welding:

- This resistance welding method allows a wide range of material types and shapes to be precisely, reliably and rapidly joined.

- Sheets, sections, strips, stampings, wires or strands are welded very accurately between pointed electrodes.

- To avoid unwanted deformation on the outer surface of the workpiece, in this method the contact electrode is designed to provide the largest possible contact surface.

- Multiple welding heads are a feasible solution for applying multiple spot welding contacts and increase the joint intensity and accuracy.

- Spot welding is a proven method for durable joining of workpieces and a broad range of weld heads is available.