You are here

Tungsten Inert Gas (TIG) welding

Micro TIG (Tungsten Inert Gas) welding, also known as pulse-arc welding, is an arc-welding process that uses a non-consumable tungsten electrode to produce an arc which creates the weld.

Micro TIG welding is a non-contact process, which, like laser welding, requires an external fixture to apply force to create proper part fit-up. It utilizes a constant current welding power supply which produces high-quality welds with minimal heat affected zone by generating arcs between the workpiece and the tungsten electrode, and using the resultant heat to create the joint.

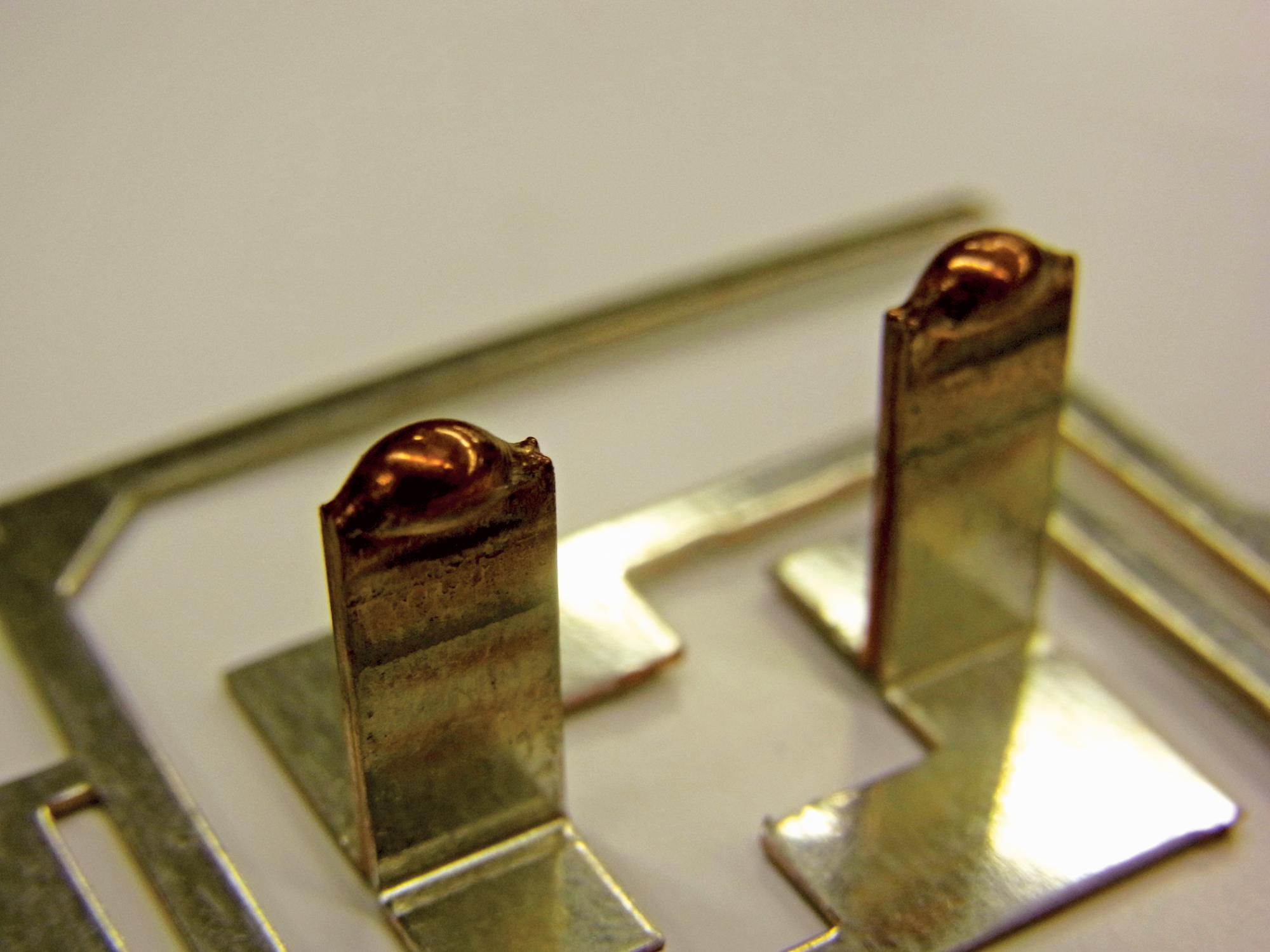

Tungsten Inert Gas (TIG) welding Micro TIG processes focus on welding small parts of a 5 mm x 5 mm area. These are usually delicate parts in the automotive, medical, or electronics industry. Pulsed arc welding has many advantages. For example, it is a solder-free process and the resultant weld is highly durable when exposed to vibration and heat. In addition, pulsed micro TIG welding is widely applicable for joining high melting point metals, dissimilar metals, and even thin magnet wires of φ0.02mm.

Two mechanisms are used to start an arc - a standard high-voltage start mechanism and a touch-start mechanism. In the former, the standoff between electrode and workpiece is set at a fixed distance. The start arc must then overcome the breakdown of air to bridge the gap. In the latter, the electrode comes down to touch the workpiece and the start arc is generated when they are in close proximity. The weld area is generally protected from atmospheric contamination by use of an inert shielding or cover gas (argon or helium).

TIG Welding Equipment

AMADA WELD TECH offers two Micro TIG welders with output power ranging from 5 – 50 A or 30 – 300 A. In addition, you will find torches and stands, Lanthanted tungsten electrodes, gas nozzles, cables and safety equipment.

AMADA WELD TECH’s micro TIG welders are ideal for welding coils and terminals, bus bars, and coated wires. These applications are commonly found in the automotive, medical, battery, and electronics industries.