Medical

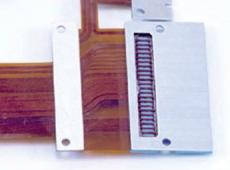

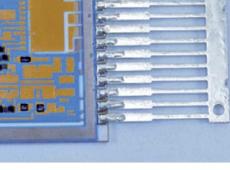

UF-2000A / UF-4000A / UF-R4000A is a new power supply for Hot Bar Reflow Soldering, Heat-Sealing, ACF Laminating and Heat Staking technologies. It utilises pulsed heat technology to provide targeted heating and precision temperature control for a variety of components including flex circuits, ribbon cables, wires, SMT components, single or dual-sided edge connectors and thermo-compression bonding of gold ribbon.

| Temperature profile specifications | |||

|---|---|---|---|

| Temperature range Idle | 25 to 300 °C | Heat | 60 to 600 °C |

| Temperature range Baseheat | 25 to 300 °C | Heat Extended Range | 60 to 999 °C |

| Temperature range Preheat | 60 to 500 °C | Postheat | 25 to 999 °C |

| Time period (in 0.1 Sec increments) base heat | 0 to 99.9 seconds | Rise to Heat Time | 0 to 9.9 seconds |

| Time period (in 0.1 Sec increments) rise to preheat time | 0 to 9.9 seconds | Heat | 0.1 to 99.9 seconds |

| Time period (in 0.1 Sec increments) preheat | 0 to 99.9 seconds or continuous | Postheat | 0 to 99.9 seconds |

| Temperature control - accuracy | ± 2% of reading or ± 6 °C whichever is greater | ||

| Temperature control - repeatability | ± 1% of reading | ||

| Thermocouple input | Type E, J, or K | ||

| Heating rate control | Three integrated user-set parameters optimize temperature profile | ||

| Interrupt function (optional) | Stop heating cycle at reach of force or displacement limit through external device | ||

| Programmable heat profiles | Sixty three (63) non-volatile memory | ||

| Switched input electrical specifications | |||

| Operator initiation | 1 or 2 level footswitch | ||

| Dedicated relays | 24 VAC/ 24 VAC 0.3A | ||

| Air head | ON/OFF for head actuation | ||

| Head cool | ON/OFF for cooling thermode holder | ||

| Solder cool | ON@COOL, OFF@PREHEAT | ||

| Programmable relays | 7 each, electromechanical (24 VAC or +24 DC) | ||

| Contact rating | 24 VAC/24DC, 0.3A | ||

| Communication ports | RS-232, RS-485 | ||

| Programmable relay functions | Reflow, preheat, baseheat, idle on, alarm, out of limits, clean thermode, replace thermode, end reflow, heat on, head valve active, system ready | ||

| PHYSICAL/ENVIRONMENTAL SPECIFICATIONS | |||

| Operating temperatures | 59°F (15° C) – 104°F (40 °C) | ||

| Relative humidity maximum | 93% @ 104°F 40 °C | ||

| POWER SUPPLY ORDERING GUIDE | |||

| UNFE2/120 UF-4000A | UF-4000A Power Supply, 120 VAC, 2kVA transformer / 15A, Single Phase 50 or 60 Hz | ||

| UNFE4/240/EAPRO UF-4000A | UF-4000A Power Supply, 240 VAC, 4kVA transformer / 15A, Single Phase 50 or 60 Hz | ||

| UNFE4/240/EAPRO UF-R4000A | UF-R4000A Power Supply, 240 VAC, no transformer / 15A, Single Phase 50 or 60 Hz |

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.