You are here

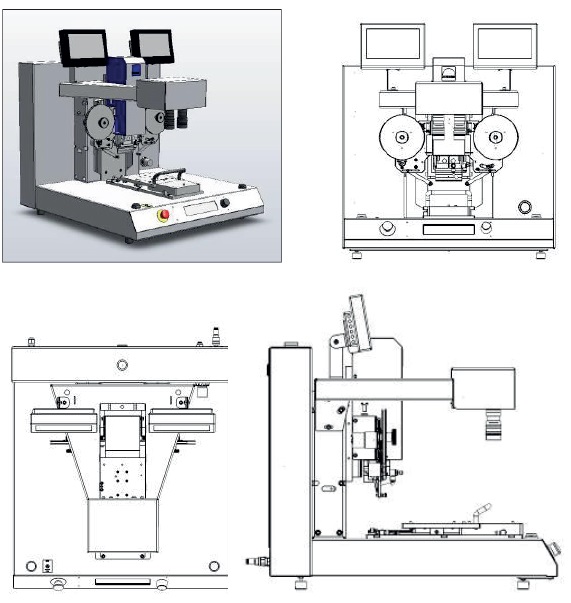

NH-2000A Series Pulsed Heat Reflow Soldering System (formerly known as MHBR )

Pulsed Heat Reflow Soldering is a slective soldering process where two pre-fluxed, solder-coated parts are heated with a thermode to a sufficient temperature to melt the solder. After this the parts are cooled below the solidification temerature to form a permanent electrodmechanical bond. The newhorizon Hot Bar systems are an integral part of the HotBar series using Pulsed Heat technology throught the UF4000A power supply, a pneumatic bond head and customized 2-D & 3-D thermodes.

The NH-2000A product range includes various models with different product handling features such as linear slides and rotary tables. The systems are designed considering ergonomic standards offering maximized production output. All process parameters are embedded into the system, ensuring consistent process quality and operator independence.

The NH-2000A systems enable full automatic process control with manual (un-)loading of parts. Each system can be adapted to suit the customer's technical requirements through extension with optional plug & play modules. All modules are mounted on a robust frame construction. The system offers the best stability supporting applications down to the finest pitch.

Key Features NH-2000A Series Pulsed Heat Reflow Soldering System

- Compact and flexible systems for high quality connections

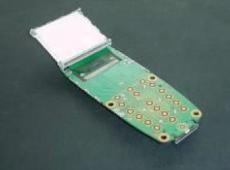

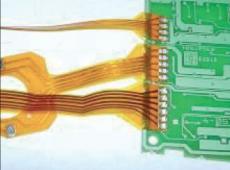

- Connecting displays to PCB, bonding glass panel displays and flex foils

- User friendly system configuration, including optional plug & play modules

- Pulsed Heat process control proven technology through UF4000A Power Supply

- Ideal price-performance (throughput) ratio

- CE approved

- Pneumatic bond head, X-Y Hot Bar planarity adjustment and electronic system control included

| Model | |||

|---|---|---|---|

| Power requirements | 100-240 VAC / Single Phase / 50/60 Hz (16 Amps max) | ||

| Air supply | 6 – 8 bar [ 87 – 116 psi ] , clean dry & filtered air | ||

| Fixture assembly baseplate dimensions | 150 x 150 mm | ||

| Fixture weight | 1,0 kg Max (per product fixture | ||

| Thermode size (length x widht) [2-D / 3-D configuration | [2-D: up to 50,0 x 3,0 mm] [3-D: up to 75,0 x 4,0 mm] | ||

| Starting operation | Two hand control | ||

| Operating temperature | 15 – 40 °C | ||

| Operating humidity | Max 93% @ 40 °C | ||

| Certification | CE Approved | ||

| Bonding head & Uniflow-4 Technical specifications | |||

| Force range | 8 – 80 N @ 6 Bar / 60 – 750 N @ 6 Bar ( applicable for both MHBR and MHSB models) | ||

| Bond head stroke (max) | 45 mm | ||

| Bond level height | 40 mm | ||

| Free Z space for components | 20 mm | ||

| Temperature range Idle | 25 to 300 °C | Heat | 60 to 600 °C |

| Temperature range Baseheat | 25 to 300 °C | Heat Extended Range | 60 to 999 °C |

| Temperature range Preheat | 60 to 500 °C | Postheat | 25 to 999 °C |

| Time period (in 0,1 sec increments) Base Heat | 0 to 99,9 seconds | Rise to Heat Time | 0 to 9,9 seconds |

| Time period (in 0,1 sec increments) Rise to preheat time | 0 to 9,9 seconds | Heat | 0,1 to 99,9 seconds |

| Time period (in 0,1 sec increments) Preheat | 0 to 99,9 seconds or continuous | Postheat | 0 to 99,9 seconds |

| Communications ports | RS-232, RS-485 | ||

| MODEL SPECIFICATIONS | |||

| NH-2100 Base | No movement | ||

| NH-2200 Linear Slide (manual 2-position front-rear slide) | Stroke between front and bonding position: 200 mm fixe | ||

| NH-2300 Rotary table (manual 2-position) | Turntable diameter: 380 mm | ||

| NH-2400 Automatic Rotary table (pneumatic 2-position) | Turntable diameter: 380 mm Turntable movement time: < 2 seconds | ||

| NH-3110 base | No movement | ||

| NH-3210 linear slide (manual 2-position front-rear slide) | Stroke between front and bonding position: 200 mm fixed | ||

| NH-3310 rotary table (manual 2-position) | Turntable diameter: 380 mm | ||

| NH-3410 Automatic Rotary table (pneumatic 2-position) | Turntable diameter: 380 mm Turntable movement time: < 2 seconds | ||

| WEIGHT & DIMENSIONS | |||

| Dimensions HxWxD (mm) | 650 x 615 x 695 (excluding Power Supply) | ||

| Weight | 60 kg (excluding Power Supply of approx. 30 kg) |

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.