You are here

F120, F160, FD120 - Spot Welding Heads for Automation

Thanks to their excellent dynamic response and their stable follow-up properties the F series weld heads represent the best solutions for a wide range of resistance welding applications. Maximum reliability and ease of maintenance generate an outstanding cost of ownership and a very long product life in operation. The F120, F160 and FD120 series is designed for welding of materials which require precise and reliable welds continuously. All three weld head types deliver outstanding weld process stability and consistent reproducibility.

The F120, F160 and FD120 weld heads are designed to be used in combination with a variety of electrodes, force sensors and power supplies.

Key features F120, F160, FD120 - Spot Welding Heads for Automation

- Modular for easy integration for automation

- Adjustable force-firing from 1.2 N to 550N

- Fast follow-up

- Ideal for safety-critical applications

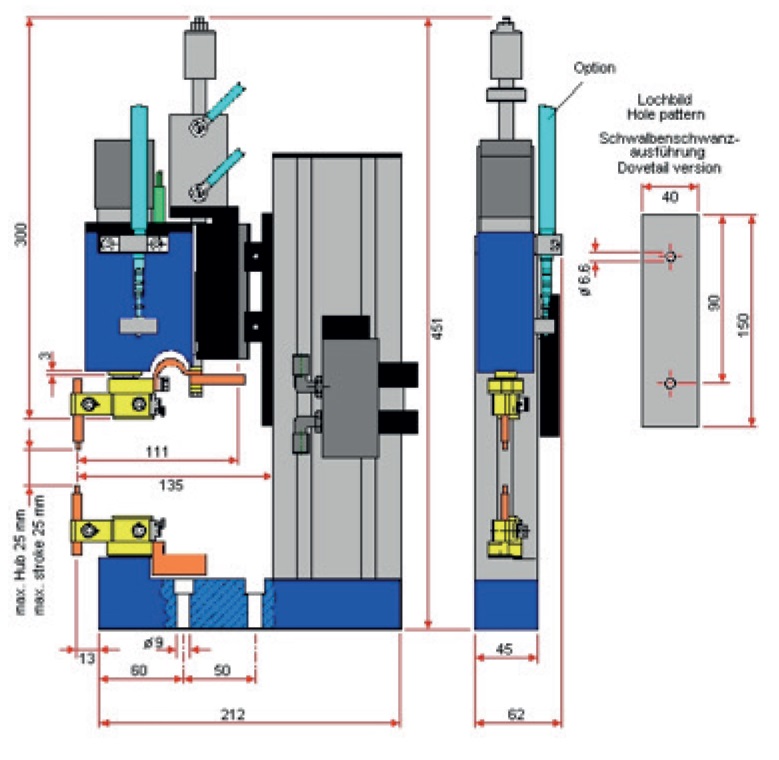

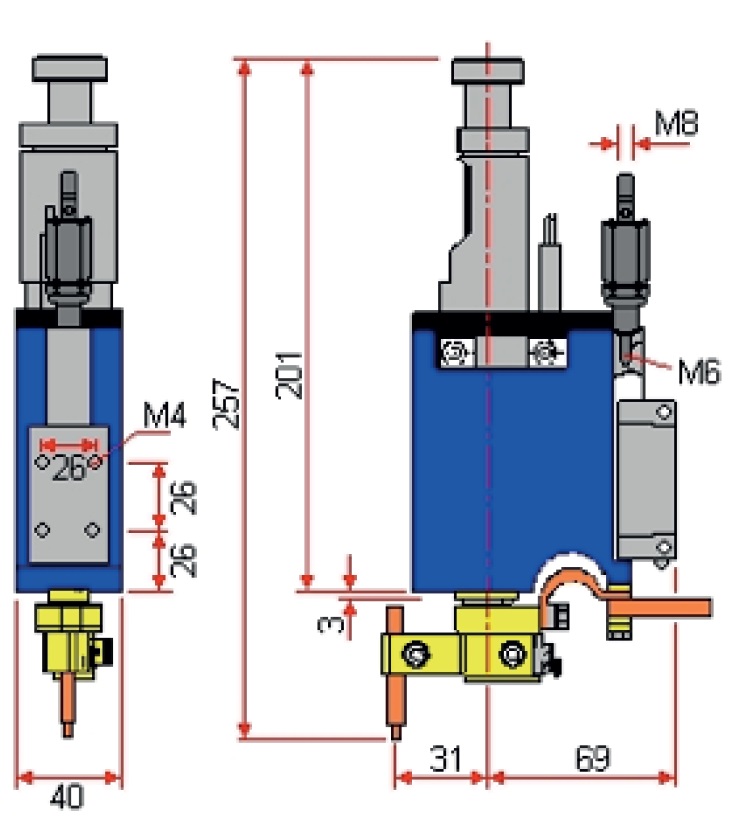

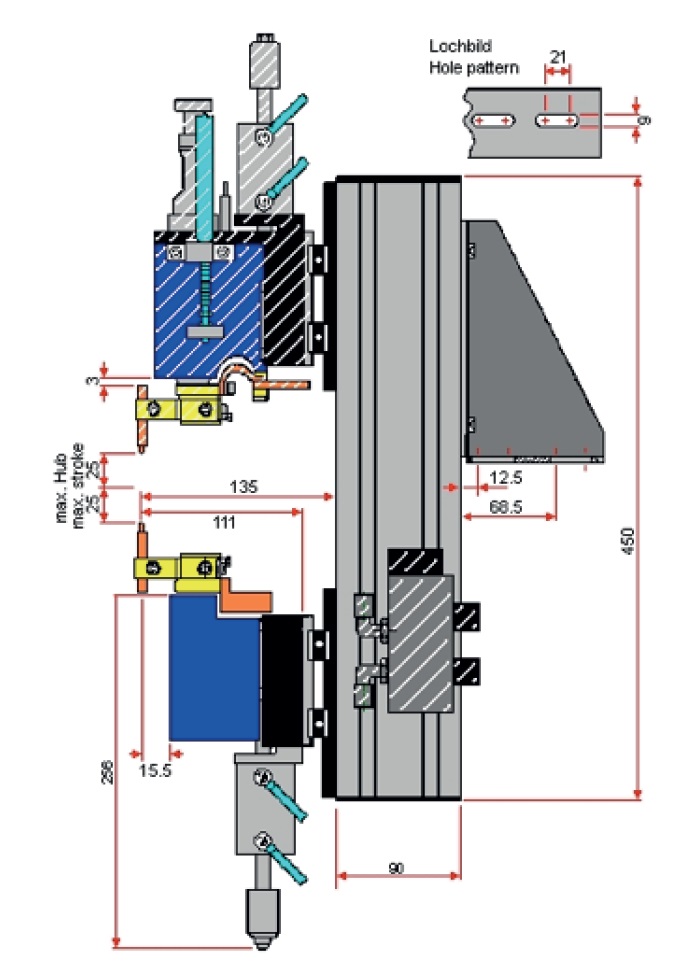

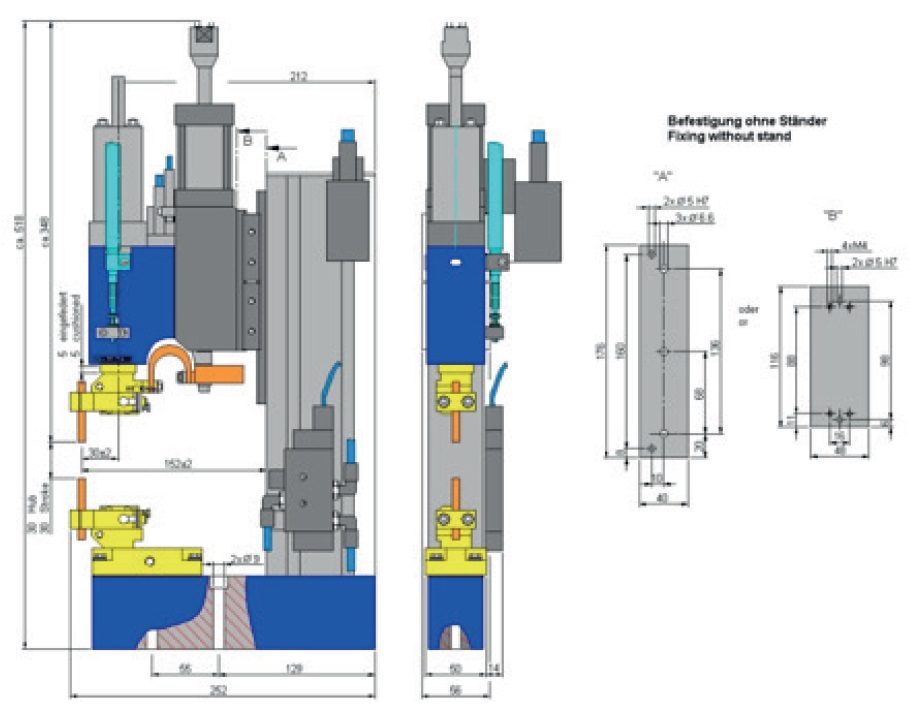

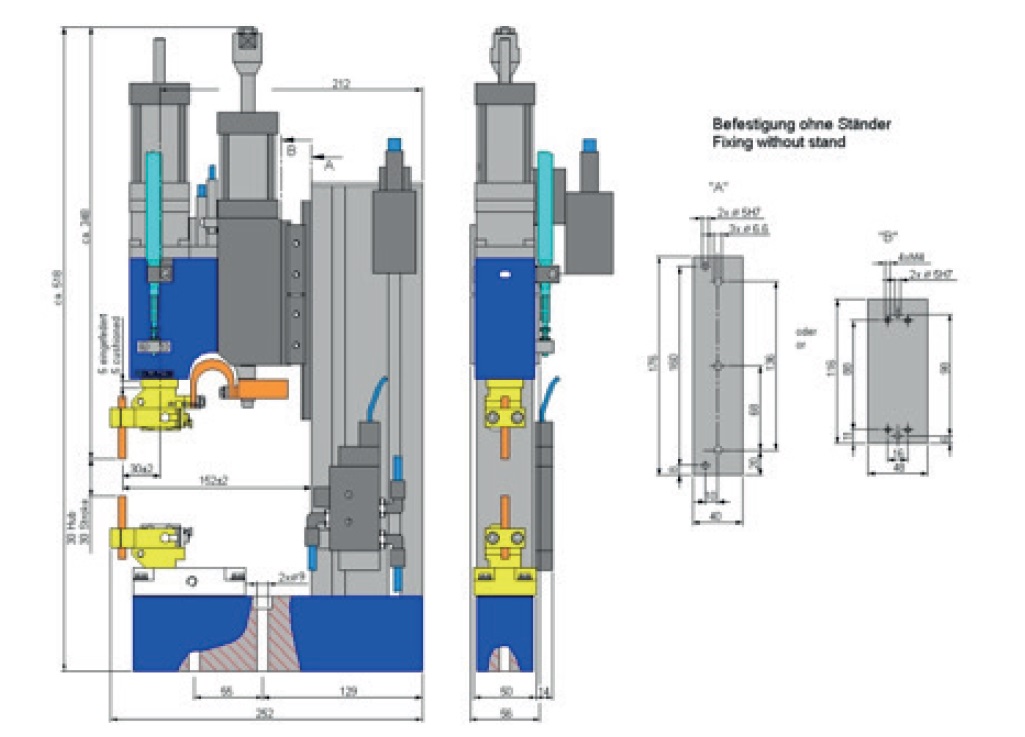

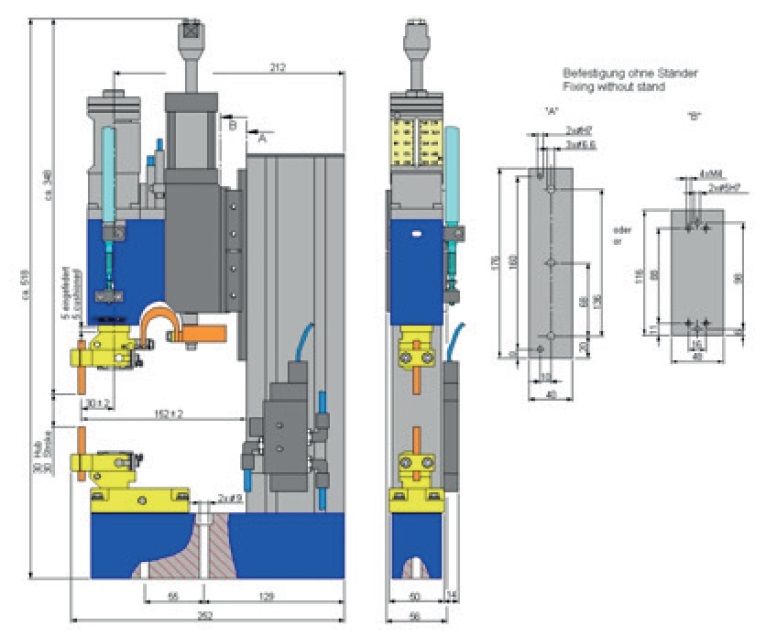

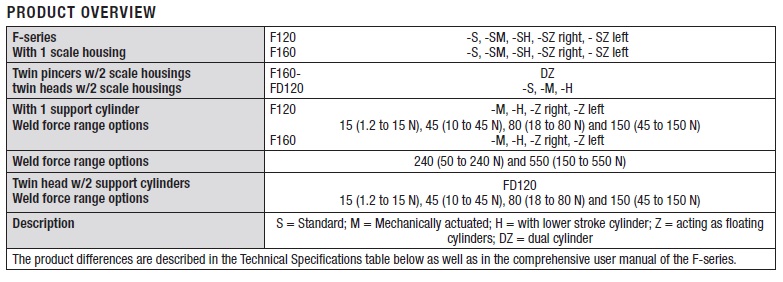

| Model | F120 | F160 | FD120 |

|---|---|---|---|

| Configuration | F120 can be equipped with three and F160 with four different springs | F120 can be equipped with three and F160 with four different springs | F120 can be equipped with three and F160 with four different springs |

| Options | Add-on set - displacement measuring sensor; automatic weld head without stand and without lower electrode holde | Add-on set - displacement measuring sensor; electrode 10 mm; anti torsion protection | With portal |

| Maximum rating | 5 kA (2 kA with light current band) | 5 kA (2 kA with light current band) | 5 kA (2 kA with light current band) |

| Electrode stroke | 25 mm | 25 mm | 25 mm |

| Closing stroke | pneumatic | pneumatic | pneumatic |

| Welding pressure | via pneumatic pre-tensioned spring | via pneumatic pre-tensioned spring | via pneumatic pre-tensioned spring |

| Weld force max | - 1.2 to 150 N -15: 1.2 to 15 N --45: 10 to 45 N -80: 18 to 80 N -150: 45 to 150 N (all depend on spring) | -240: 50 to 240 N -550: 150 to 550 N (all depend on spring) | 15 to 150 N (depends on spring) |

| Air pressure supply | max 6 bar | max 6 bar | max 6 bar |

| Weld force adjustment | -S and FD versions: adjustable screws on the scale housing - All other versions: via adjustable pressure control valve or proportional valve | -S and FD versions: adjustable screws on the scale housing - All other versions: via adjustable pressure control valve or proportional valve | -S and FD versions: adjustable screws on the scale housing - All other versions: via adjustable pressure control valve or proportional valve |

| Electrode shape | cylindrical, d = 6 mm | cylindrical, d = 6 mm | cylindrical, d = 6 mm |

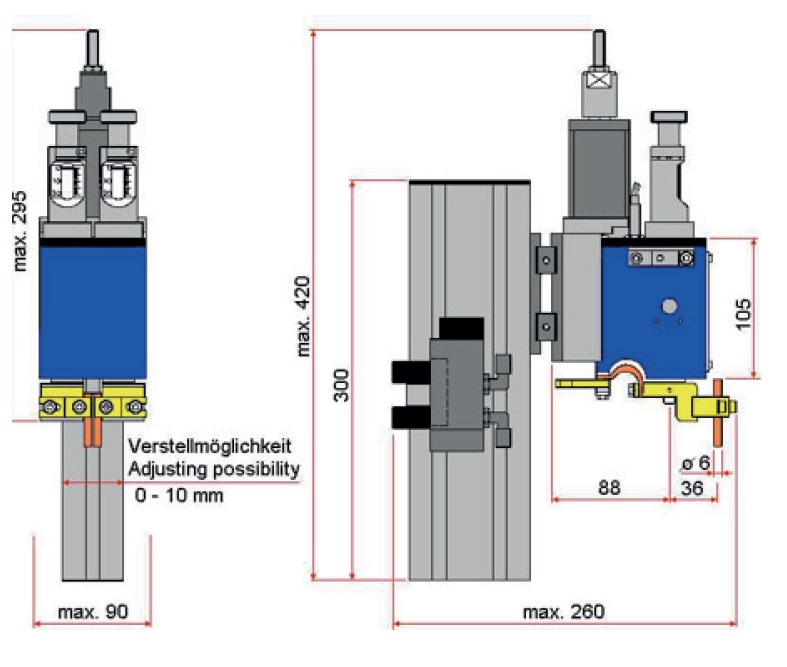

| Electrode holder | quick change holder made of gold-plated aluminium at the top and bottom | quick change holder without antitorsion protection for electrodes | variable distance (max 10 mm) between the electrodes |

| Weld cables | 2x95 mm², 700 mm long | 4x95 mm², 700 mm long | 2x95 mm², 700 mm long |

| Environment temp. | 0-40 °C | 0-40 °C | 0-40 °C |

| Weight | from 5,5 to 7 kg | approx. 8 kg | approx. 5,5 kg |

| Dimensions (WxHxD) | vary | vary | 260x420x90 mm |

Documentation

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.