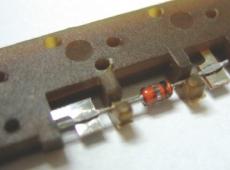

Resistor to terminal

The HF2 High Frequency Inverter Spot Welding Power Supply recisely controls and monitors electrical AND mechanical weld parameters. Miniature welds are highly sensitive to small heat profile fluctuations in the resistance welding process. Overheating deforms and destroys parts, while underheating results in a weak and unacceptable bond. To achieve consistent, reliable welds of small to micro-miniature parts, heating needs to be precisely controlled. This necessitates superior control of the energy output.

| Control system | 2 KHz pulse width modulated (PWM) inverter welding control with constant current, voltage or power feedback operating modes. Feedback response every 250 microseconds. | ||||

|---|---|---|---|---|---|

| Line voltage | Three phase, 208, 230, 380 or 460 VAC ±13%, 50/60 Hz | ||||

| Input circuit rating | HF2/208-50 A: HF2/230-50 A; HF2/380-30 A; HF2/460-30 A | ||||

| Weld current | 0.05 – 4.0 kA | ||||

| Weld power | 0.10 – 9.99 kW | ||||

| Weld voltage | 0.1 – 5.0 V | ||||

| Weld period | 2000 milliseconds (maximum) | ||||

| Graphical weld display | Graphical display of programmed and actual weld current, voltage and power | ||||

| Welding functions | 10 functions – basic, braze, dual pulse, pre/weld/post heat, pulsation, quench/te per, roll-spot, weld/repeat, up/down slope and seam | ||||

| Weld schedules | The user can save (write) 128 different weld schedules. Weld schedules 1 through 127 can be protected. Schedule O is designed to be used as a scratchpad for schedule development. | ||||

| Input signals | . | ||||

| Remote control external input connector | Provides control for the following remote control signals: emergency stop, weld inhibit and remote weld schedule selection. Use dry relay contacts or optocouplers to control remote external input signals. | ||||

| Firing switch | 1-level footswitch, 2-level footswitch, 2-wire firing switch, 3-wire firing switch and optofiring switch. Use dry relay contact or opto-couplers to control input signals. | ||||

| Output signals | . | ||||

| Solid state relays | 2 user-programmable solid state relays: AC-24/115 VAC @ 15 VA: DC-24 VDC @ 15 VA. | ||||

| Valve driver outputs | 2 solid state relay outputs for controlling air actuated weld heads. Valve #1 can control a single 24/115 VAC air head. Valve #2 can control a single 24 VAC air head. | ||||

| HF2 transformer model | IT-X3A/230 | IT-X3A/380 | IT-X3A/460 | IT-X11A/230 | IT-X11A/460 |

| Nominal AC input voltage | 208/240 | 400 | 480 | 208/240 | 400/480 |

| Input KVA (50%) duty cycles | 9 | 9 | 9 | 19 | 15 |

| Number of primary taps | 1 | 1 | 1 | 2 | 4 |

| Turn ratio | 46:1 | 90:1 | 109:1 | 25:1/30:1 | Turns Ratios: 44:1, 52:1, 60:1, 68:1 |

| Maximum unloaded output voltage (v) | 6.5 | 6.5 | 6.5 | 10.0/12.0 | 11.8/14.3 |

| Maximum output current (A) | 4,000 | 4,000 | 4,000 | 4,000 | 4,000 |

| Duty cycle (%) at max. current | 6 | 5 | 5 | 5 | 5 |

| Model | Inverter | IT-X3A/230 IT-X3A/380 IT-X3A/460 | IT-X11A/230 | IT-X11A/460 | |

| Dimensions (LxWxH) | 381 mm x 267 mm x 216 mm (15 in x 10.5 in x 8.5 in) | 368 mm x 183 mm x 183 mm (14.5 in x 7.2 in x 7.2 in) | 455 mm x 183 mm x 183 mm (17.9 in x 7.2 in x 7.2 in) | 470 mm x 183 mm x 183 mm (18.5 in x 7.2 in x 7.2 in) | |

| Weight | 19 kg (42 lb) | 13 kg (29 lb) | 25 kg (56 lb) | 26 kg (58 lb) |

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.