Solar cell

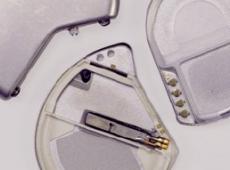

Designed for use in automation or benchtop welding, AMADA WELD TECH's 70 Series Weld heads offer stable, repeatable electrode force for a wide range of resistance welding applications. Two different models are available, each equipped with an easy-to-program, state-of-the-art servo motor controller which allows the electrode positions to be precisely programmed and a speed of up to 32 different weld schedules.

Programmable electrode positions – accurate to .004 in

| Model number | Model 71 | Model 72 | |

|---|---|---|---|

| Head type | Opposed | Parallel | |

| Force range | 0.25 – 8 lbs.* | 0.25 – 8 lbs.* per electrode | |

| Weld force method | Spring force setting | Spring force setting | |

| Actuation method | Servo motor | Servo motor | |

| Electrode stroke | 1.5 in max. (.004 in steps) | 1.5 in max. (.004 in steps) | |

| Throat depth inches | 4 | 8 | |

| Number of schedules | 32 (selectable externally) | 32 (selectable externally) | |

| Electrode speed | Start point – Mid point – 8 speeds adjustable by schedule (20-300 mm/s) Mid point – Welding point – 4 speeds adjustable by schedule (7.5-30 mm/s) 8 settings (100, 200, 300, 400, 500, 1000, and 2000 ms, external END signal) | Start point – Mid point – 8 speeds adjustable by schedule (20-300 mm/s) Mid point – Welding point – 4 speeds adjustable by schedule (7.5-30 mm/s) 8 settings (100, 200, 300, 400, 500, 1000, and 2000 ms, external END signal) | |

| Power supply | 100 - 220 VAC 50/60 Hz | 100 - 220 VAC 50/60 Hz | |

| Welding current | 3000 amps @ 2% DC | 3000 amps @ 2% DC | |

| Model number | Model 71 | Model 72 | Controller |

| Dimensions (LxWxH) | 216 mm x 80 mm x 300 mm (8.5 in x 3.14 in x 11.8 in) | 404 mm x 120 mm x 270 mm (15.9 in x 4.7 in x 10.6 in) | 243.8 mm x 63.5 mm x 154.9 mm (9.6 in x 2.5 in x 6.1 in) |

| Weight | 7.7 lbs (3.5 kg) | 16 lbs (7.3 kg | 6.6 lbs (3 kg) |

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.