Tu sei qui

CD-A - Advanced Capacitive Discharge Welder

The CD-A Advanced Capacitive Discharge Welder features dual pulse output control, internal pulse monitoring, optional polarity switching and is automation capable.

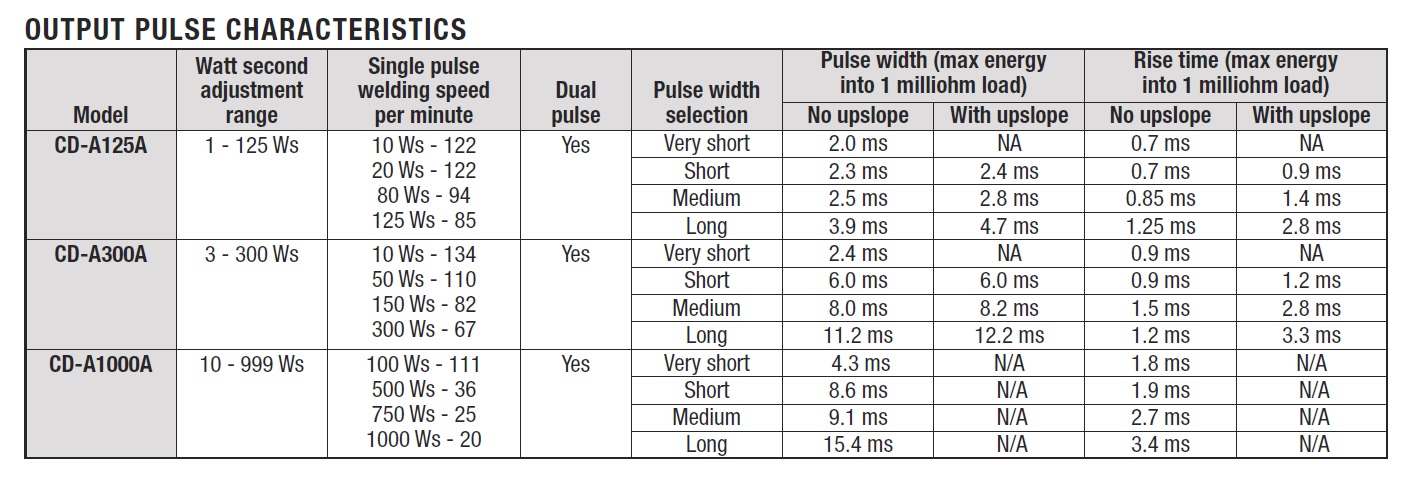

The unit offers consistent welding output for repeatable process results, with ultrafast rise time for conductive material welding. Featuring fully controllable dual pulse output, the CD-A provides pulse shaping with 4 discrete pulse lengths, programmable squeeze and hold times and adjustable pulse separation. Furthermore, the units offer the ability to set limits around a schedule to prevent bad welds and a built-in peak current indicator which indicates the last weld peak current. The ability to change polarity – individual settings for positive, negative, or alternating polarity – allows for a way to balance weld nuggets and overcome the Peltier effect, as well as extend electrode life.

The CD-A welder is automation ready and can be easily integrated into production lines. The unit can be programmed to communicate with a host computer or with an automation control system. Operators can set and store up to 63 schedules to quickly change between weld parameters. A schedule chaining feature lets users automatically switch between two different schedules. The power supplies enable rapid fire between pulses for quick welding of adjacent locations.

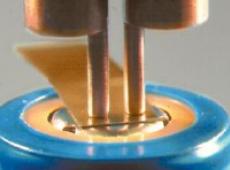

The CD-A Advanced Capactive Discharcge Welder is ideal for battery tab welding, interconnects, honeycomb tacking and fine wire to pad applications.

Key Features CD-A - Advanced Capacitive Discharge Welder

- Dual pulse function helps overcome surface inconsistencies

- Built-in monitor measures peak current for both pulses for process monitoring

- Process monitor features a color coded bar graph on the RUN screen that provides instant weld history of In Limit/ Out of Limit percentages to assess process performance

- Upper and lower limits can be set for both pulses, with an option to inhibit Pulse 2 if Pulse 1 is out of limits. Prevents weld blow out

- Upslope function allows gradual ramping of weld energy to alleviate weld splash

- Automatic polarity switching between pulses provides even heating between electrodes and increases electrode life

- Up to four software selectable pulse widths increases the range of welding applications and improves process optimization

- Efficient power electronics provide high repetition rates

| Feature | CD-A125A / CD-A300A / CD-A1000A |

|---|---|

| Tensione linea di ingresso | 90 - 138 VAC, 50 - 60 Hz ; 180 - 264 VAC, 50 - 60 Hz |

| Doppio impulso | Yes |

| Uscita trasmissione testa aria | 24 V, DC or AC – 0.5 A Max. |

| Programmi di saldatura | 63 |

| Programmi in serie (Passo automatico) | Yes |

| Tempo di pressione programmabile | Programmable per schedule from 0 - 2.999 sec |

| Programmable hold time | Programmable per schedule from 0 - 2.999 sec |

| Selezione programma remoto | Yes |

| Polarità programmabile | Positive/Negative/Alternating |

| Cicalino fine ciclo | Yes |

| Relè di uscita | Weld Ready, Weld End, Counter Limit, Alarm, Out of Limits |

| Controllo microprocessore | Yes |

| Contatore saldatura con limite programmabile dall’utente | Yes |

| Lingue | English, Spanish, German |

| MASSA E DIMENSIONI | |

| Dimensions (LxWxH) CD-A125A | 388 mm x 261 mm x 375 mm (15.25 in x 10.26 in x 14.76 in) |

| Weight CD-A125A | 20 kg (44 lbs) |

| Dimensions (LxWxH) CD-A300A | 388 mm x 261 mm x 375 mm (15.25 in x 10.26 in x 14.76 in) |

| Weight CD-A300A | 31 kg (69 lbs) |

| Dimensions (LxWxH) CD-A1000A | 388 mm x 261 mm x 375 mm (15.25 in x 10.26 in x 14.76 in) |

| Weight CD-A1000A | 31 kg (69 lbs) |

Documentation

Soluzioni personalizzate

Inviate un campione a uno dei nostri centri tecnologici in Europa per una valutazione. Valuteremo la soluzione che soddisfa meglio le vostre esigenze. AMADA WELD TECH conduce test di fattibilità e eroga consulenza applicativa.