Seam weld example

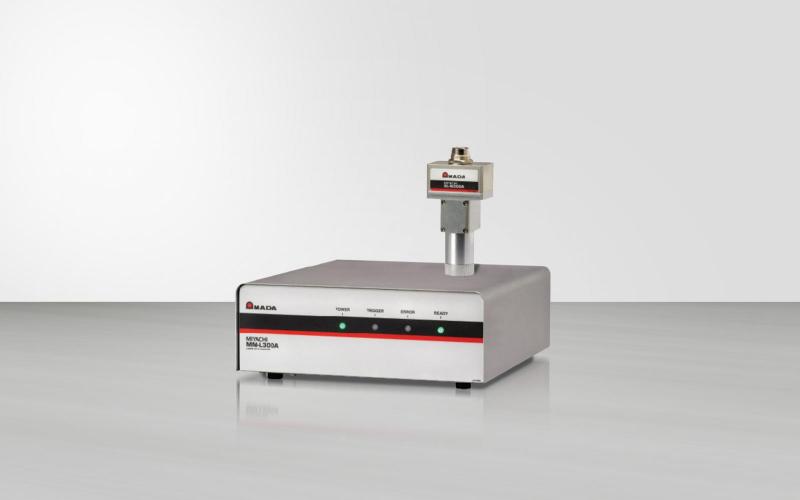

The MM-L300A laser weld monitor helps to ensure weld quality and maintain high throughput by providing realtime feedback during the laser welding process to ensure weld success. MM-L300A works by detecting and recording a thermal signal from the area of laser interaction during the welding process. The SU-N300A thermal sensor samples the signal and provides an output waveform around which envelope limits can be set.

| MM-L300A Controller | . |

|---|---|

| Input power requirements | Single phase, 90 – 250 VAC 50/60 Hz |

| Interfaccia | 15 pin D-sub, Ethernet (RJ-45) |

| Channel | 1 |

| Temporal resolution | Min: 1 μs |

| Judgement function: Analysis | Waveform |

| Judgement function: Judgement | Upper and lower limit |

| Operational temperature range | 0 – 40° C (non-condensing) |

| Operational humidity range | |

| SU-N300A sensor | . |

| Monitoring area | Working distance approx. 200 mm, Signal detection diameter - about ø 2 mm |

| Guide light | Green LED |

| Monitoring wavelengths | 1,300 – 2,500 nm |

| Operational temperature range | 5 – 50°C (non-condensing) |

| Operational humidity range | |

| Protection level | IP64 with connector |

| MASSA E DIMENSIONI | |

| MM-L300A without connector dimensions (LxWxH) | 243 mm x 230 mm x 89 mm (9.6 in x 9.1 in x 3.5 in) |

| MM-L300A without connector weight | 3.0 kg (6.6 lb) |

| Sensor without connector dimensions (LxWxH) | 35 mm x 50 mm x 96 mm(1.4 in x 2 in x 3.8 in) |

| Sensor without connector weight | 0.2 kg (0.44 lb) |

Inviate un campione a uno dei nostri centri tecnologici in Europa per una valutazione. Valuteremo la soluzione che soddisfa meglio le vostre esigenze. AMADA WELD TECH conduce test di fattibilità e eroga consulenza applicativa.