Seam weld example

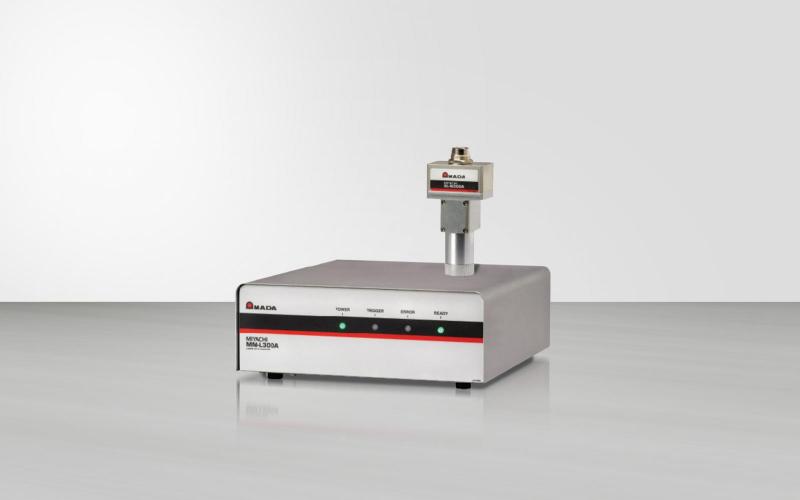

The MM-L300A laser weld monitor helps to ensure weld quality and maintain high throughput by providing realtime feedback during the laser welding process to ensure weld success. MM-L300A works by detecting and recording a thermal signal from the area of laser interaction during the welding process. The SU-N300A thermal sensor samples the signal and provides an output waveform around which envelope limits can be set.

| MM-L300A Controller | . |

|---|---|

| Input power requirements | Single phase, 90 – 250 VAC 50/60 Hz |

| Interface | 15 pin D-sub, Ethernet (RJ-45) |

| Channel | 1 |

| Temporal resolution | Min: 1 μs |

| Judgement function: Analysis | Waveform |

| Judgement function: Judgement | Upper and lower limit |

| Operational temperature range | 0 – 40° C (non-condensing) |

| Operational humidity range | |

| SU-N300A sensor | . |

| Monitoring area | Working distance approx. 200 mm, Signal detection diameter - about ø 2 mm |

| Guide light | Green LED |

| Monitoring wavelengths | 1,300 – 2,500 nm |

| Operational temperature range | 5 – 50°C (non-condensing) |

| Operational humidity range | |

| Protection level | IP64 with connector |

| WEIGHT & DIMENSIONS | |

| MM-L300A without connector dimensions (LxWxH) | 243 mm x 230 mm x 89 mm (9.6 in x 9.1 in x 3.5 in) |

| MM-L300A without connector weight | 3.0 kg (6.6 lb) |

| Sensor without connector dimensions (LxWxH) | 35 mm x 50 mm x 96 mm(1.4 in x 2 in x 3.8 in) |

| Sensor without connector weight | 0.2 kg (0.44 lb) |

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.