You are here

TR-T0016A - Touch Retract Welding Torch

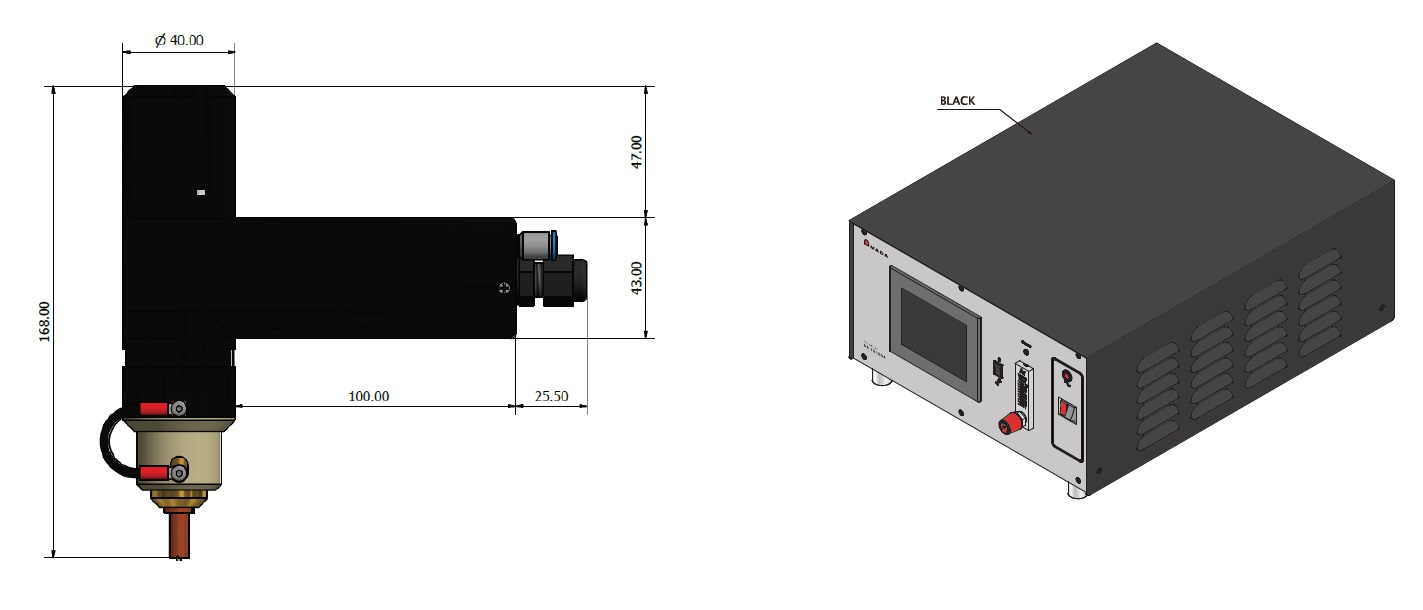

The innovative TR-T0016A Touch Retract TIG Torch is a hand-held tool that has been developed for the welding of conductive thin-sheet material. Providing consistent welding performance in an easy to use form, the TR-T0016A Touch Retract TIG Torch is ideal for the assembly of battery modules and packs.

Traditionally, Nickel has been the first choice for current connectors within battery packs as it is easy to weld with Resistance Welding technology. Switching from Nickel to Copper tabs can improve battery performance by 20% however its conductive nature makes Resistance Welding a challenge. Micro-Arc welding is a highly efficient method for generating localised heat.

The TR-T0016A Touch Retract TIG Torch has been designed exclusively for use in combination with our PA-T200A Percussive Arc Power Supply which incorporates the necessary power electronics to facilitate highly controlled welds and interfacing with modern industrial communications systems.

Key features TR-T0016A - Touch Retract Welding Torch

- Suitable for welding multiple battery designs in many battery pack configurations.

- Protruding electrode and narrow nozzle (7mm) for easy weld location control.

- Integrated collar for machine integration for upscaling manufacturing capacity.

- Narrow nozzel for easy, repeatable weld location

- Low voltage arc.

- Light weight, ergonomic design for easy operator manipulation.

| Model | TR-T0016A Touch Retract Welding Torch |

|---|---|

| Electrode size | 1.6 mm |

| Maximum current | 200A |

| Actuation | Hand held or machine mountable |

| WEIGHT & DIMENSIONS | TR-T0016A Touch Retract Welding Torch |

| Weight | 550 gram (Touch Retract Welding Torch) |

| Nozzle diameter | 7 mm |

| Model | PA-T200A Power Supply |

| Maximum Output Current | 200A |

| Duty cycle | 5%@150A |

| Open circuit voltage | 45V D.C. |

| Options | 1 output only |

| Mains supply 50/60Hz | 380/415/480 VAC 3-phase |

| WEIGHT & DIMENSIONS | PA-T200A Power Supply |

| Weight | 42 kg |

| Dimensions (WxHxD) | 560 x 220 x 445 mm |

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.