You are here

C16, C16-D, C25, C70 - Compacting Equipment

Resistance Welding Compacting is ideally suited for stranded wires, sensors and Y connectors. It applies an eve, intense and massive compression. As compared to ultrasonic methods the surface of a compacted Resistance Welding wire is even and uniform. There are no individual strands in the compacting areas. Compacting delivers an even and uniform wire surface. Combined with the brazing technique compacting is ideally suited to join cables of a large dimension in automotive applications such as the intelligent battery sensor application which allows for smart battery power management. The compacted wire diameter may be up to 16, 25 or 70 mm2.

| Model | C16 | C16D | C25 | C70 |

|---|---|---|---|---|

| Configuration | Single or double compacting unit for a copper braid with a diameter of up to 16 mm2 | Single or double compacting unit for a copper braid with a diameter of up to 16 mm2 | Single compacting unit for a copper braid with a diameter of up to 25 mm2 | Single compacting unit for a copper braid with a diameter of up to 70 mm2 |

| Air pressure supply | max. 6 bar | max. 6 bar | max. 6 bar | max. 6 bar |

| Copper braid diameter | Up to 16 mm2* | Up to 16 mm2* | Up to 25 mm2* | Up to 70 mm2* |

| Compacting braid shape | Rectangular or square | Rectangular or square | Rectangular or square | Rectangular or square |

| Electrode force, compacting length, distance settings | Depend on application and configuration | Depend on application and configuration | Depend on application and configuration | Depend on application and configuration |

| Environment temp. | 0-40 °C | 0-40 °C | 0-40 °C | 0-40 °C |

| Cooling | Water cooled | Water cooled | Water cooled | Water cooled |

| Options | Digital Resistance Welding Monitoring with MG3 | Digital Resistance Welding Monitoring with MG3 | Digital Resistance Welding Monitoring with MG3 | Digital Resistance Welding Monitoring with MG3 |

| * | Exact ranges depend on the application. AMADA WELD TECH is pleased to recommend a suitable configuration for compacting devices which meets the specific needs. | |||

| WEIGHT & DIMENSIONS | ||||

| Weight approx. | 2,5 kg | 4 kg | 3 kg | 18 kg |

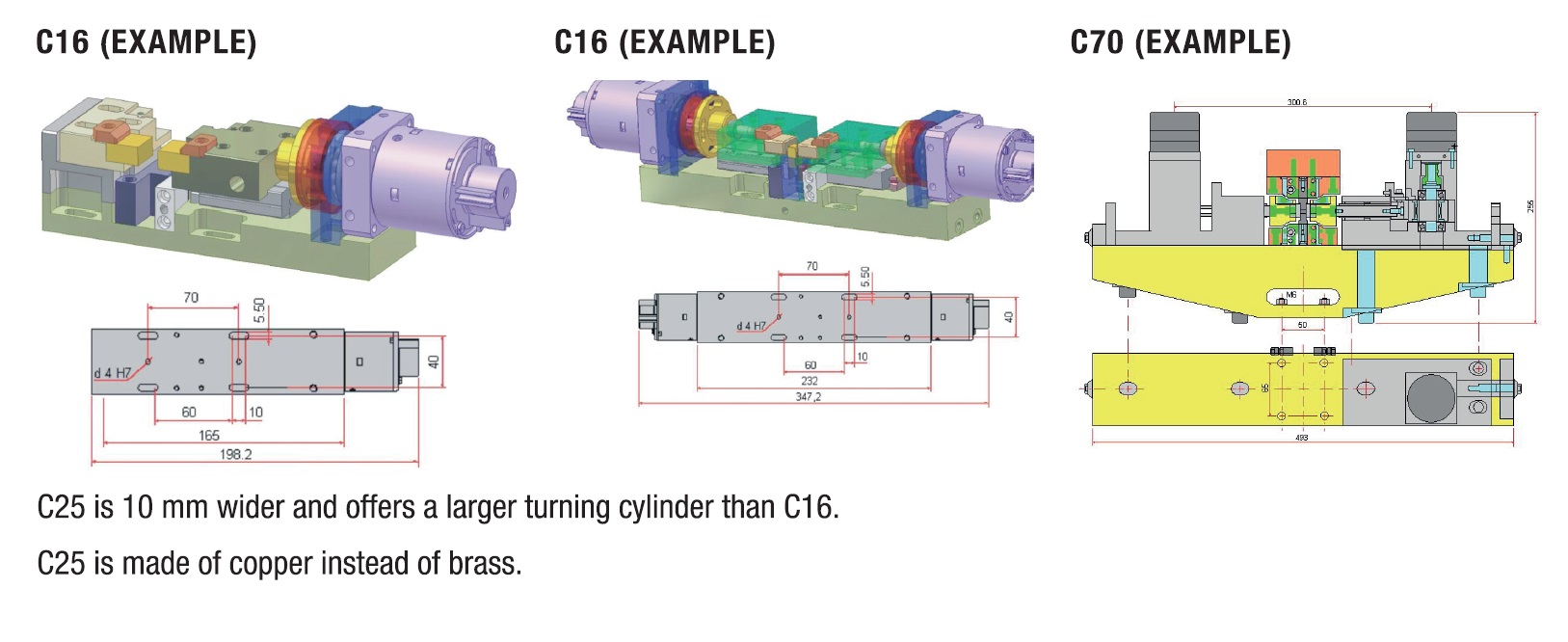

| Dimensions (LxHxD) | See drawings below | See drawings below | See drawings below | See drawings below |

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.