You are here

Lighting

Many lamp welding applications require the joining of small diameter tubing, wires, thin foils, the modification of reflector moulds, bracket welding for lighting fixtures and so on. To create reliable welds, fine control and parameter monitoring are necessary.

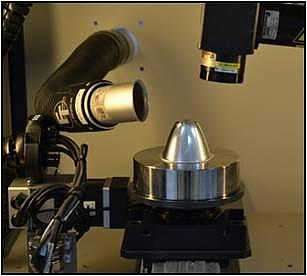

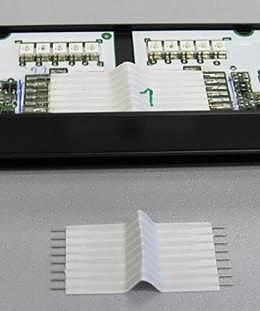

Our laser welding, laser marking, resistance welding, reflow soldering, ACF laminating, heat sealing and heat staking technologies are used on many applications throughout the lighting industry. These include automotive head lamps, lamp filaments, dashboard display lighting, LED reflectors, energy-saving lamps, down-light reflectors, spot light reflectors, torch reflectors, LED reflectors, photographic flash lamps and other industrial lamp assemblies. The end products are widely used for commercial lighting, photographic lighting, domestic lighting and stage lighting areas.