Jelenlegi hely

ACF Bonding: Creating reliable electronic interconnections

for fine pitch applications

Used primarily for connecting displays to printed circuit boards (PCBs), anisotropic conductive film (ACF) bonding results in a smaller, lighter end product, by eliminating the need for connectors. ACF Bonding reduces or eliminates bridging issues, one of the most common failures of soldering.

ACF Bonding is gaining substantial interest as a way of improving reliability and potentially provide substantial cost savings. It serves as an alternative to connectors and soldering and proves to be a more cost-effective option than traditional connectors. ACF eliminates the risk of short circuits, which are often a concern associated with soldering. Moreover, ACF's compatibility with automation makes it a more fitting choice when compared to these alternatives.

ACF Bonding Principle

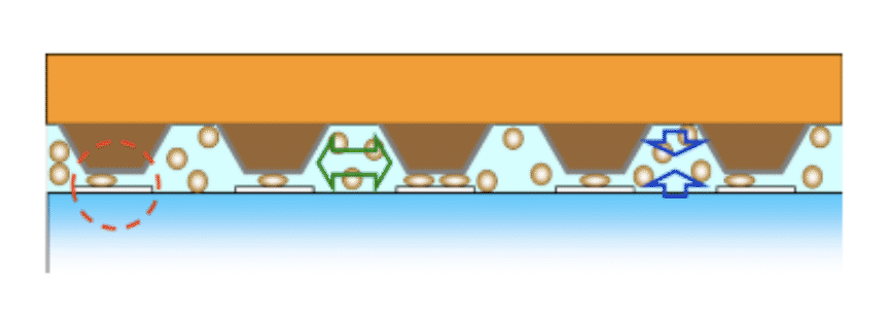

ACF Bonding is the process of creating electrically conductive bonds through heating and cooling conductive adhesive whilst applying pressure. Using a thermode, thermal energy is transferred to both parts when applying pressure, with the ACF providing electrical connection, insulation, and adhesion. ACF can be either acrylic-based or epoxy- based, depending on the requirements of the client and/or materials being bonded. The thickness of the ACF layer and/or the nature of the conductive particles can be varied due to the geometry of the materials being bonded.

ACF Bonding in Automobile and Smart Home Applications

Self-driving vehicles, for example Mercedes-Benz EQS, with Drive Pilot Level 3, have an increasing demand for sensors, radar, lidar and cameras with (ACF bonded) fine pitch interconnections. Next to automobile applications, the various smart home applications are also a considerable growth area for ACF Bonding. The smart solutions all contain interconnected parts. In fact, ACF can be a good fit anywhere flexible materials need to be bonded. New applications being investigated include electronic shelf labels, solar cells, sensors, cameras and (ADAS) safety features.

Why Choose ACF Bonding?

ACF has many benefits, including the reliability, performance and functionality of interconnections, the suitability for a broad range of applications, as well the low cost and simplified manufacturing processes. In comparison, connectors may be more expensive and more difficult to incorporate into automated processes, while soldering requires higher processing temperatures which may damage nearby components. In some cases, soldering of fine pitch applications may prove to be impossible, due to risks of short or bridged circuits. The ACF interconnection can be placed at the edge of the board and is also flat, requiring no vertical space. ACF interconnection is also lead-free and suitable for flexible materials. Its conductivity remains high and stable during heat and humidity tests.

Three key parameters define ACF Bonding success:

- Material: PCB and flex design

- Equipment: Power supply, thermode design, bonding head

- Process: Bonding head settings, positioning, bonding force

Do’s and Don’ts of ACF Bonding

1. Flex growth is possible, so be aware. A large heat sink in the PCB might increase the risk of flex growth since the thermode temperature must be set at higher level. However, a flex can be designed to compensate for flex growth.

2. Tooling design should secure part positioning and offer proper alignment functionality. Selecting the correct tooling materials can prevent heatsink.

3. Design the parts for alignment and test visibility of fiducials.

4. Design the parts with correct tolerances and planarity. It’s much easier to design the correct parts than adjust the process later.

Success is a Partnership

Successful ACF bonding is a joint effort between the ACF supplier, product owner, and equipment supplier. For example, AMADA WELD TECH supports feasibility testing free of charge, offers modules for system integration with laminating (bond head, interposer, ACF feeder) and final bonding process modules (bond head,

UF-4000A and time controller, interposer, 3D thermodes, and MG-300A process monitor). Configured systems are available in two types. The NH desktop series can be configured with standard components while the advanced desktop series offer more customization. The NH desktop series offer a cost-effective solution, while the advanced desktop series offers more versatility.