Jelenlegi hely

Jupiter Advanced Laser Welding System

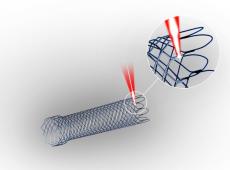

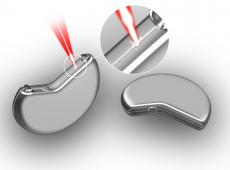

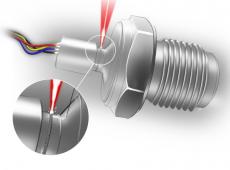

The Jupiter Advanced LW System is a series of Cartesian CNC workstations for laser welding of precision parts with the highest quality. AMADA WELD TECH offers its expertise to all of its customers to correctly match any welding application with the right laser welder, fibers, optics, tooling and process parameters. Our Laser Welders can join a wide range of (stainless) steels, nickel alloys, titanium, aluminum and copper. Typical laser welding applications include seam sealing of implantable medical devices, stents, guide wires, catheters, high frequency aerospace radar components, spot welding of small mechanical parts, battery housings, hermetic seam welding of sensors, etc.

Key Features of the Jupiter Advanced Laser Welding System

- Modular, stand-alone system adaptable to customers requirements

- Class-1 safety enclosure fulfills CE safety regulations

- High accuracy servo motor motion system

- Standard 3 CNC programmable axes (X,Y,Z), expandable to 5 (by adding 2 rotary axes)

- CNC G-code contour programming with powerful extensions

- Aerotech CNC controller platform

- Industrial PC for maximum certainty on product recipe and data logging storage

- PSLF (Position Synchronized Laser Firing) option to match laser output to a variable motion speed along a contour

- IMS3000 (Integrated Manufacturing Software) for integral production recipes, storing and loading of all relevant product parameters in one central database (laser, CNC, vision, operator work instructions, etc.)

- Advanced FDA/Mil-Spec compliant data logging (system messages, laser performance, serial and batch numbers and external power meter measurements)

- Integrated Remote Service and diagnostics

| MODEL SPECIFICATIONS | Pulsed Nd-YAG | CW Fiber | QCW Pulsed Fiber |

|---|---|---|---|

| Average power levels (W) | max. 600 | max. 4000 | max. 450 |

| Peak power levels (W) | max. 10000 | max. 4000 | max. 4500 |

| Peak energy levels (J/pulse) | max. 100 | n.a. | max. 45 |

| Wavelength | 1064 nm | 1070 nm or 1080 nm | 1070 nm |

| Laser head | Several options possible, incl. CCTV versions | Several options possible, incl. CCTV versions | Several options possible, incl. CCTV versions |

| Collimator lens focal distance (mm) | 50 to 200 | 35 to 70 | 50 to 200 |

| Focal lens focal distance (mm) | 50 to 200 | 50 to 200 | 50 to 200 |

| Optical fiber diameter (µm) | 100 to 1000 | 10 to 1000 | 50 to 200 |

| Effective spot sizes (µm) | 100 to 1000 | 10 to 600 | 50 to 600 |

| Optical fiber length (m) | 5 to 40 | 5 to 20 | 5 |

| -------------------------------------- | |||

| TECHNICAL SPECIFICATIONS AXES | X-axis | Y-axis | Z-axis |

| Löket | 430 mm | 350 mm | 180 mm |

| Ismételhetőség | ± 6 µm | ± 6 µm | ± 20 µm |

| Velocity | 300 mm/s | 300 mm/s | 190 mm/s |

| -------------------------------------- | |||

| Opció | Rotary R-axis | ||

| Static repeatability | 0.05 º | ||

| Rotational frequency | 66 º/s (11 rpm) | ||

| . | |||

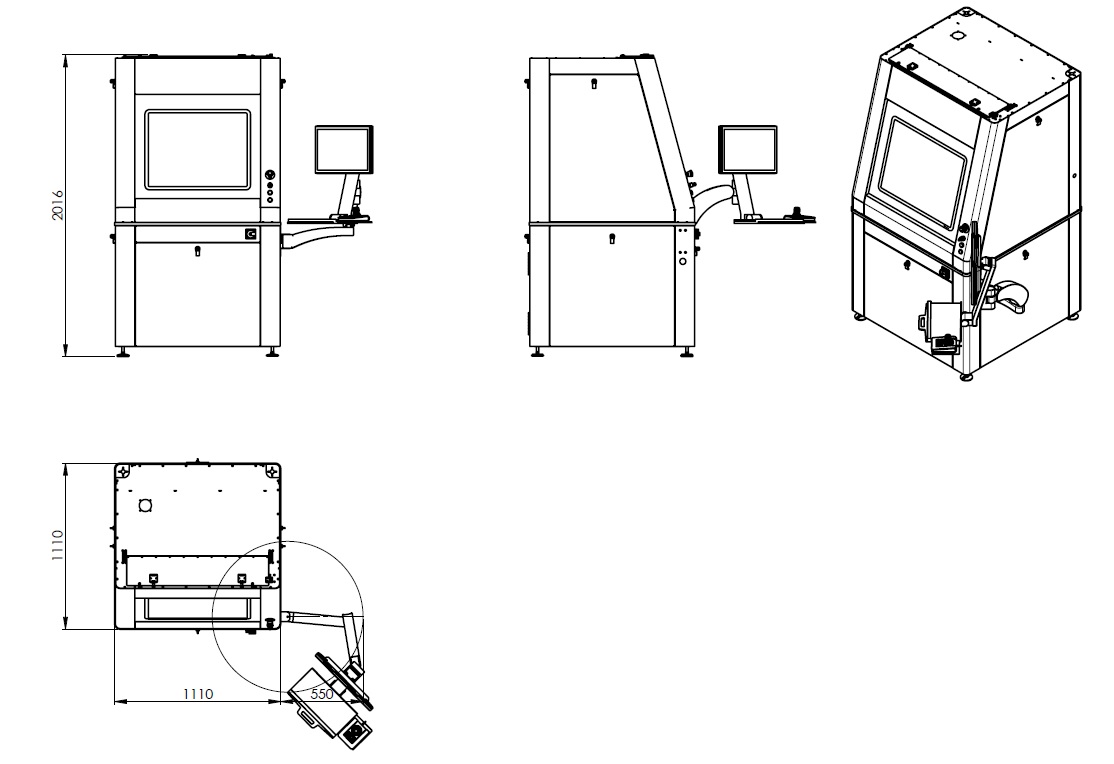

| SÚLY ÉS MÉRET | Jupiter Advanced Laser Welding system | ||

| Méretek magas x széles x mély (mm) | 2013 x 1110 x 1110 (excl. laser, chiller & fume extraction unit) | ||

| Méretek magas x széles x mély (mm) | 2400 x 1415 x 110 (door opened and incl. HMI) | ||

| Súly | ± 600 kg (depending on options) |

Testre szabott megoldások

Mintáját küldje be valamelyik európai technológiai központba kiértékelésre. Ennek alapján meghatározzuk, hogy melyik megoldás felel meg a legjobban az Ön igényeinek. Az AMADA WELD TECH felajánlja a megvalósíthatóság tesztelését, valamint az alkalmazással kapcsolatos tanácsadást is.