You are here

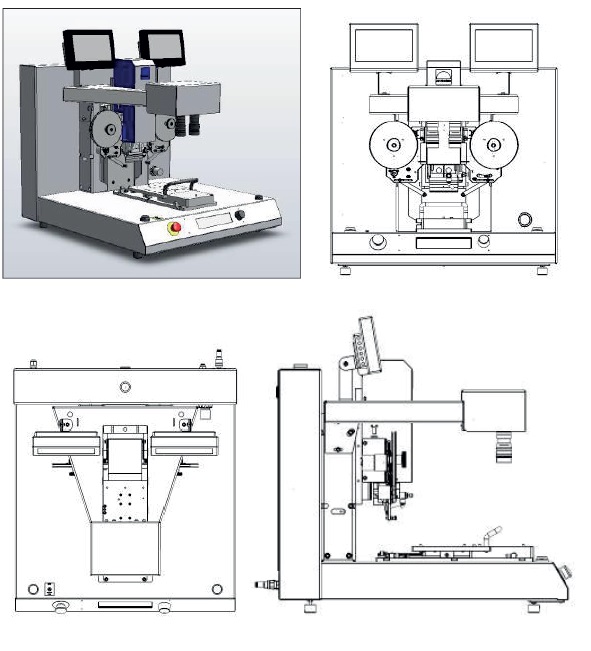

NH-3000A Series ACF Final Bonding system PH (formerly known as MHSB)

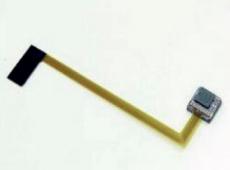

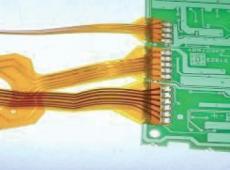

Depending on your specific application, MIYACHI's NH-3000 Series Heat Seal Bonding / Heat Staking Systems are available in two versions – a version using Constant Heat technology and another version using Pulsed Heat technology. The NH-3000 Series Heat-Seal Bonding systems are fully integrated, bonding systems which join parts utilizing our proven, constant heat or pulsed heat technologies, a pneumatic bonding head and a customized hot bar thermode. The bond head can apply up to 750 Newtons of force which makes it ideal for flex-to-pcb and flex-to-LCD applications.

Key features NH-3000 Series ACF Final Bonding system PH

- Compact and flexible systems for high quality connections

- Connecting displays to PCB, bonding glass panel displays and flex foils

- User friendly system configuration, including optional plug & play modules

- Pulsed Heat process control proven technology through Uniflow-4 Power Supply

- Ideal price-performance (throughput) ratio

- CE approved

- Pneumatic bond head, X-Y Hot Bar planarity adjustment and electronic system control included

| Power requirements | 100-240 VAC / Single Phase / 50/60 Hz (16 Amps max) |

|---|---|

| Air pressure supply | 6 – 8 bar [ 87 – 116 psi ] , clean dry & filtered air |

| Fixture assembly baseplate dimensions | 150 x 150 mm |

| Fixture weight | 1,0 kg max (per product fixture) |

| Thermode size (length x width) 2-D / 3-D configuration) | [2-D: up to 50,0 x 3,0 mm] [3-D: up to 75,0 x 4,0 mm] |

| Starting operation | Two hand control |

| Operating temperature | 15 – 40 °C |

| Operating humidity | Max 93% @ 40 °C |

| Certification | CE Approved |

| Force range | Bonding head: 60 – 750 N @ 6 Bar |

| Bond head stroke (max) | 45 mm |

| Bond level height | 40 mm |

| Free Z space for components | 20 mm |

| Temperature range Idle | 25 to 300 °C |

| Temperature range Baseheat | 25 to 300 °C |

| Temperature range Preheat | 60 to 500 °C |

| Temperature range Heat | 60 to 600 °C |

| Temperature range Heat Extended Range | 60 to 999 °C |

| Temperature range Postheat | 25 to 999 °C |

| Time period (in 0,1 sec increments) Base Heat | 0 to 99,9 seconds |

| Time period (in 0,1 sec increments) Rise to preheat time | 0 to 9,9 seconds |

| Time period (in 0,1 sec increments) Preheat | 0 to 99,9 seconds or continuous |

| Time period (in 0,1 sec increments) Rise to heat time | 0 to 9,9 seconds |

| Time period (in 0,1 sec increments) Heat | 0,1 to 99,9 seconds |

| Time period (in 0,1 sec increments) Postheat | 0 to 99,9 seconds |

| Communications ports | RS-232, RS-485 |

| MHSB-3110 base | No movement, stroke between front and bonding position: 200 mm fixed |

| MODEL SPECIFICATIONS | |

| NH-3310 rotary table (manual 2-position) | Turntable diameter: 380 mm |

| NH-3410 Automatic Rotary table (pneumatic 2-position) | Turntable diameter: 380 mm; Turntable movement time: < 2 seconds |

| WEIGHT & DIMENSIONS | |

| Dimensions HxWxD (mm) | 650 x 615 x 695 (excluding Power Supply) |

| Weight | 60 kg (excluding Power Supply of approx. 30 kg) |

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.