Sie sind hier

UB-4000A Lineare DC-Punktschweißsteuerung mit eingebautem Monitor (ehemals DC29)

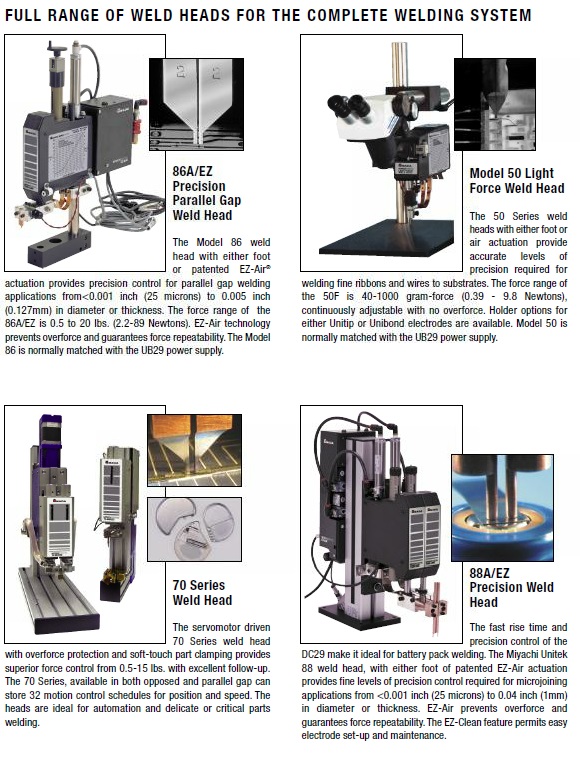

Die lineare UB-4000A DC-Widerstandsschweißsteuerung mit 200 bis 4000 Ampere und vier Rückkopplungsmodi wurde zur Anpassung an Teile- und Prozessvariablen ausgelegt. Die Schweißenergie kann in den Einheiten Strom, Spannung, Leistung oder V-A (Spannung-Strom) in Schritten von nur 0,01 Millisekunden programmiert werden. Daher ist dieses Punktschweißgerät ideal für kleine Anwendungen in den Märkten für elektronische Bauteile und Batteriepacks geeignet.

Spezifikationen UB-4000A Lineare DC-Punktschweißsteuerung mit eingebautem Monitor

- Vier Regelmodi: Strom, Spannung, Leistung und V-A (Spannung-Strom)

- Einphasiger Eingang

- Kompakte Größe

- Doppelimpuls-Zeitpläne

- Präzis gesteuerte wiederholbare Wellenform

- Sehr schnelle Anstiegszeit

| Modellnummer | UB-500A | UB-1500A | UB-4000A | |||

|---|---|---|---|---|---|---|

| Nennnetzspannungen (einphasig) | 88-264 VAC 47-63 Hz | 88-264 VAC 47-63 Hz | 88-264 VAC 47-63 Hz | |||

| Repetierrate | 500 A @ 3 weld/sec for 10 ms (per weld) | 1500 A @ 1 weld/sec for 10 ms (per weld) | 4000 A @ 1 weld/sec for 10 ms (per weld) | |||

| Einstellbereiche: Strom | 5A-500A 1 amp/step | 15A-1500A 1 amp/step | 200 A - 4000 A 10 amp/step | |||

| Einstellbereiche: Spannung | 0.01 V - 9.9 V 10 mV/step | 0.1 V - 9.9 V 10 mV/step | 0.1 V - 9.9 V 10 mV/step | |||

| Einstellbereiche: Leistung | 0.05 kW - 4.99 kW 10 Watt/step | 0.1 kW - 9.9kW 10 Watt/step | 0.1 kW - 25.0kW 10 Watt/step | |||

| Spitze: Strom | 500 A | 1500 A | 4000 A | |||

| Spitze: Spannung | 10 V | 10 V | 10 V | |||

| Spitze: Leistung | 4.9 kW | 9.9 kW | 25.0 kW | |||

| Leistungsregelung im Vergleich zu Netzspannungsvarianz | 2% | 2% | 2% | |||

| Leistungsregelung im Vergleich zu Lastwiderstandsvarianz | 2% | 2% | 2% | |||

| Schweißzeitbereiche | Ranges (ms) | Resolution (steps) | Ranges (ms) | Resolution (steps) | Ranges (ms) | Resolution (steps) |

| Erster/Zweiter Impuls, Stromanstieg/Stromabfall und Kühlperioden | 0 - 99.9 | .1(0-9.9), 1(10-99) | 0 - 99.9 | .1(0-9.9), 1(10-99) | 0 - 99.9 | .1(0-9.9), 1(10-99) |

| Squeeze/hold periods | 0-999 | 1 | 0-999 | 1 | 0-999 | 1 |

| Ausgabegenauigkeit: Strom | ±2% or 2.5 A | ±2% or 7 A | ±2% or 10 A | |||

| Ausgabegenauigkeit: Spannung | ±2% or 0.05 V | ±2% or 0.05 V | ±2% or 0.05 V | |||

| Ausgabegenauigkeit: Leistung | ±5% or 12 W | ±5% or 40 W | ±5% or 50 W | |||

| Merkmale | . | |||||

| Schweißwärmeprofilsteuerung | UB-500A | UB-1500A | UB-4000A | |||

| Schweißimpulssteuerung | Dial pulse with independent control of current, voltage or power on each pulse | Dial pulse with independent control of current, voltage or power on each pulse | Dial pulse with independent control of current, voltage or power on each pulse | |||

| Programmierbare Schweißimpulssegmente | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | Squeeze, upslope 1, weld 1, downslope 1, cool, upslope 2, weld 2, downslope 2, hold | |||

| Schweißplan-Speicher | Save up to 99 different weld schedules, protected from unauthorized changes | Save up to 99 different weld schedules, protected from unauthorized changes | Save up to 99 different weld schedules, protected from unauthorized changes | |||

| Weld schedule chaining | Allows automatic linking of weld schedule sequence | Allows automatic linking of weld schedule sequence | Allows automatic linking of weld schedule sequence | |||

| Built-in weld monitor functions | ||||||

| Messparameter | Current, voltage, power, resistance on each pulse. | Current, voltage, power, resistance on each pulse. | Current, voltage, power, resistance on each pulse. | |||

| Grafikdisplay | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | Back-lit LCD displays programmed and actual weld current, voltage, power, or resistance and upper and lower limits | |||

| Measurement selection | Peak or average | Peak or average | Peak or average | |||

| Strommessbereich/-genauigkeit | 0 – 500 A, ±2% of setting ±5 A | 0 – 1500 A, ±2% of setting ±10 A | 0 – 4000kA, ±2% of setting ±20 A | |||

| Spannungsmessbereich/-genauigkeit | 0.1 – 9.9 V, ±2% of setting ±0.05 V | 0.01 – 9.9 V, ±2% of setting ±0.05 V | 0.01 – 9.9 V, ±2% of setting ±0.05 V | |||

| Leistungsmessbereich/-genauigkeit | 0 – 4.9 kW, ±5% of setting ±10 W | 0 - 9.99 kV, ±2% of setting ±40 W | 0 – 25.0 kW, ±5% of setting ±50 W | |||

| Alarme | Display alert, five user programmable AC/DC relays; audio alarm | Display alert, five user programmable AC/DC relays; audio alarm | Display alert, five user programmable AC/DC relays; audio alarm | |||

| Programmierbare Schweißenergiegrenze | Terminates weld energy when exceeding user defined current, voltage, or power limits | Terminates weld energy when exceeding user defined current, voltage, or power limits | Terminates weld energy when exceeding user defined current, voltage, or power limits | |||

| Schweißvorprüfung | Inhibits second weld pulse when first test pulse exceeds user programmed limits | Inhibits second weld pulse when first test pulse exceeds user programmed limits | Inhibits second weld pulse when first test pulse exceeds user programmed limits | |||

| Aktiver Teilekonditionierer | First pulse current limit in constant power | First pulse current limit in constant power | First pulse current limit in constant power | |||

| E/A- und Datenkommunikation | ||||||

| Input: Input Isolation | All inputs and outputs are fully isolated | All inputs and outputs are fully isolated | All inputs and outputs are fully isolated | |||

| Input: Control voltages | +24V, sourcing or sinking inputs | +24V, sourcing or sinking inputs | +24V, sourcing or sinking inputs | |||

| Input: Foot switch initiation | 1-level foot switch, 2-level foot switch | 1-level foot switch, 2-level foot switch | 1-level foot switch, 2-level foot switch | |||

| Input: Firing switch initiation | Mechanical or opto firing switch | Mechanical or opto firing switch | Mechanical or opto firing switch | |||

| Input: Remote control | Remote weld schedule select, process inhibit, emergency stop, alarm reset | Remote weld schedule select, process inhibit, emergency stop, alarm reset | Remote weld schedule select, process inhibit, emergency stop, alarm reset | |||

| Input: RS232 | Change weld schedules and individual parameters | Change weld schedules and individual parameters | Change weld schedules and individual parameters | |||

| Input: Electrode voltage | Weld voltage signal for voltage feedback operation (0 to 10V peak) | Weld voltage signal for voltage feedback operation (0 to 10V peak) | Weld voltage signal for voltage feedback operation (0 to 10V peak) | |||

| Output: Monitor | RS232 weld data out | RS232 weld data out | RS232 weld data out | |||

| Output: Weld head air valve driver | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | 24 VAC, 0.5 A; timing controlled by UB Series Power Supply | |||

| Output: Alarm relays | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | Five user-programmable opto isolated relays; programmable normally open or normally closed contacts: 30 VDC at 0.5 A Conditions: weld, end of weld, alarm, out of limits, ready, weld counter | |||

| Abmessungen (L x B x H) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | 381 mm x 213 mm x 305 mm (15 in x 8.4 in x 12 in ) | |||

| Gewicht | 22 kg (49 lb) | 22 kg (49 lb) | 22 kg (49 lb) |

Documentation

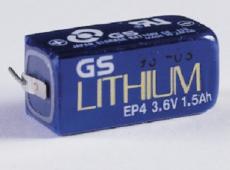

Battery tab to lithium ion cell

Halogen lamp filaments

Catheter guide wire assembly

Air bag detonator module (squib wire)

Maßgeschneiderte Lösungen

Schicken Sie Ihr Muster zur Bewertung an eines unserer Technologiezentren in Europa. Wir werden dann ermitteln, welche Lösung Ihren Bedürfnissen am besten entspricht. AMADA WELD TECH bietet Machbarkeitstests und Anwendungsberatung an.